Looking for a reliable, high-quality solution for protecting your wires and cables? Look no further than the Ultra-Thin Wall Corrosion-Resistant Transparent PTFE Heat Shrinkable Tube from Volsun.

Crafted from premium materials and designed to meet even the most demanding of applications, this heat shrinkable tube boasts impressive corrosion resistance and durability, allowing it to effectively protect your wiring against environmental factors like heat, moisture, and UV rays, as well as against chemical exposure.

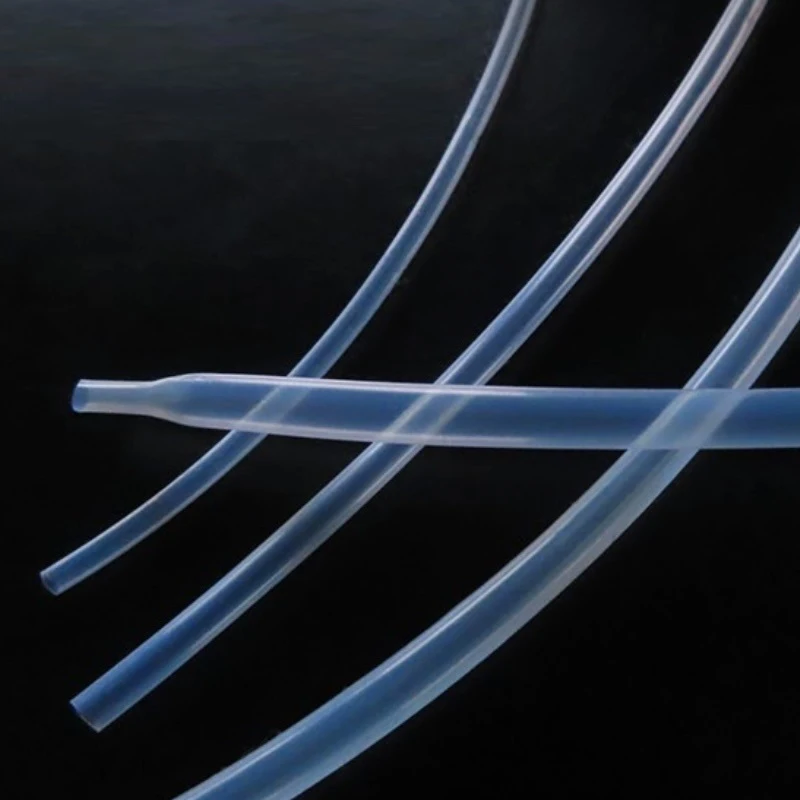

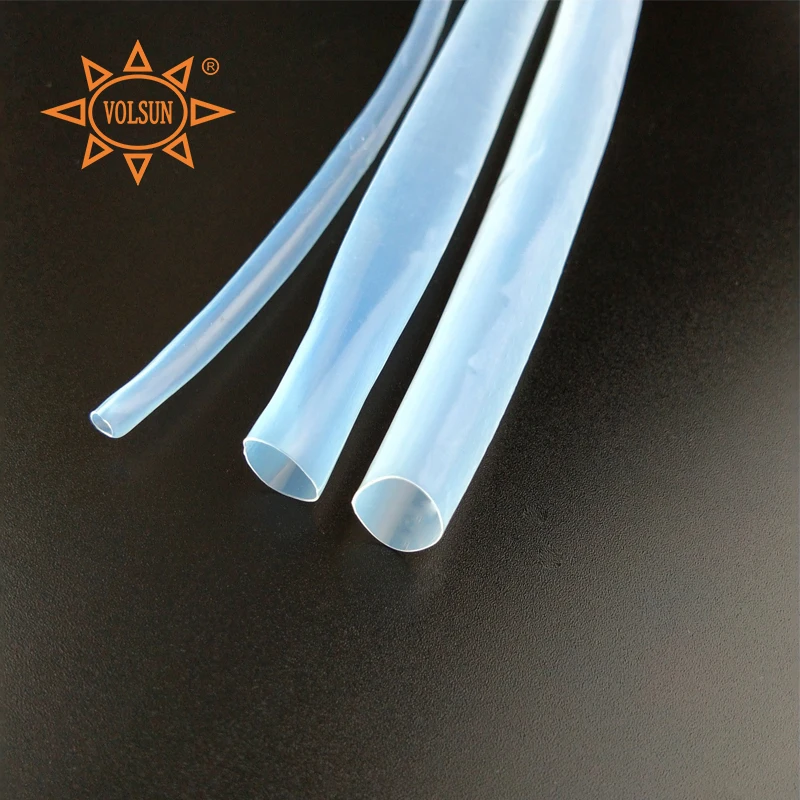

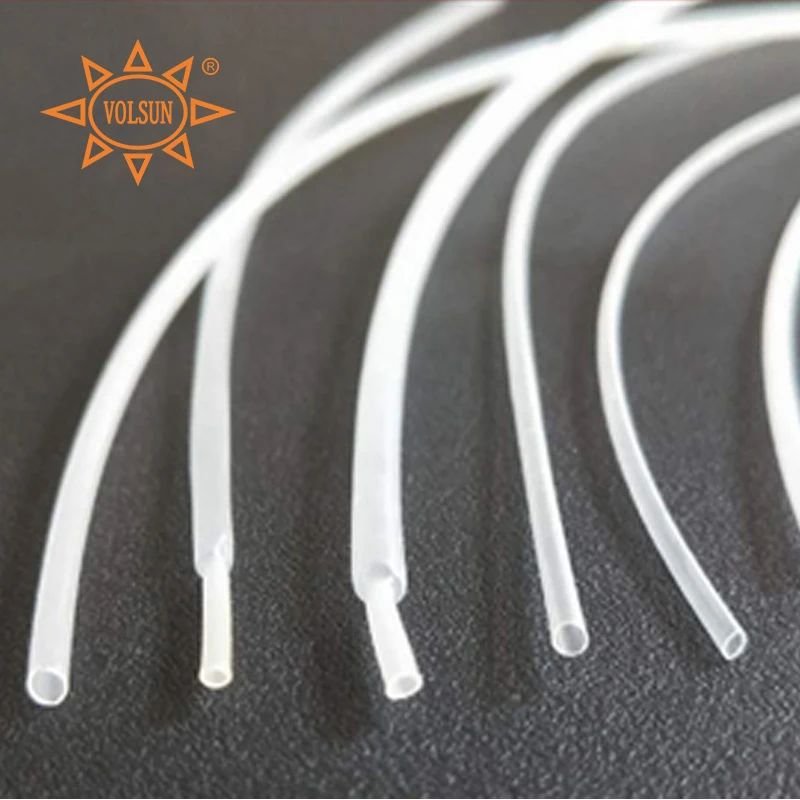

In addition to its exceptional durability and resistance to environmental factors, the Volsun’s Ultra-Thin Wall Corrosion-Resistant Transparent PTFE Heat Shrinkable Tube also offers exceptional transparency, ensuring that you can easily monitor your wiring and make any necessary maintenance or repair adjustments with ease.

And with its ultra-thin wall design, this heat shrinkable tube offers low minimum shrink temperatures and fast, reliable installation, making it ideal for a wide range of applications across industries.

Whether you're looking to protect the wiring in your home, office, or industrial facility, the Volsun’s Ultra-Thin Wall Corrosion-Resistant Transparent PTFE Heat Shrinkable Tube is the solution you need. So, why wait? Invest in the best and enjoy superior protection for your wiring today

TZRS-PTFE260 (1.7X 4X)

Teflon PTFE Heat Shrink Tubing

A highly flame retardant heat shrinkable tubing manufactured from modified PTFE Provides insulation and mechanical protection in severe chemical and thermal environments Thin wall, high shrink ratio, flexible and transparent Major uses: electrical insulation, protection of electronic components, covering of hydraulic hose and couplings, prevention against contamination and corrosion High mechanical strength and extremely low coefficient of friction make it ideal for reducing damage to bearing shafts etc

Features:

1. Continuous operating temperature: -65°C~260°C

2. Resistant to corrosion, strong acid, strong base, chemical reagents, and oil etc

3. Shrinkable temperature: ≥327℃

4. Excellent electrical performance that does not change with the temperature and frequency

5. Excellent mechanical performance, shock proof, high elasticity

6. Ultra low friction coefficient, highly flame retardant7. Flammability: VW-1

8. Shrink Ratio: 1.7:1, 4:1

9. Standard color: clear/transparent

|

|

|

|

Standard package M/roll、M/pcs

|

|

Inner Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Special sizes and packages can be customized upon request

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions for over 17 years

Quality is our culture. Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

Up to now, Volsun cooperated with customers from 88 countries, we offer suitable sealing, waterproof solutions for some well-know enterprises in communication, Automobile, Power industry etc

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

MOQ |

1 |

Supply capability |

1,000,000 pieces per month |

Lead time |

Usually 5-7 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

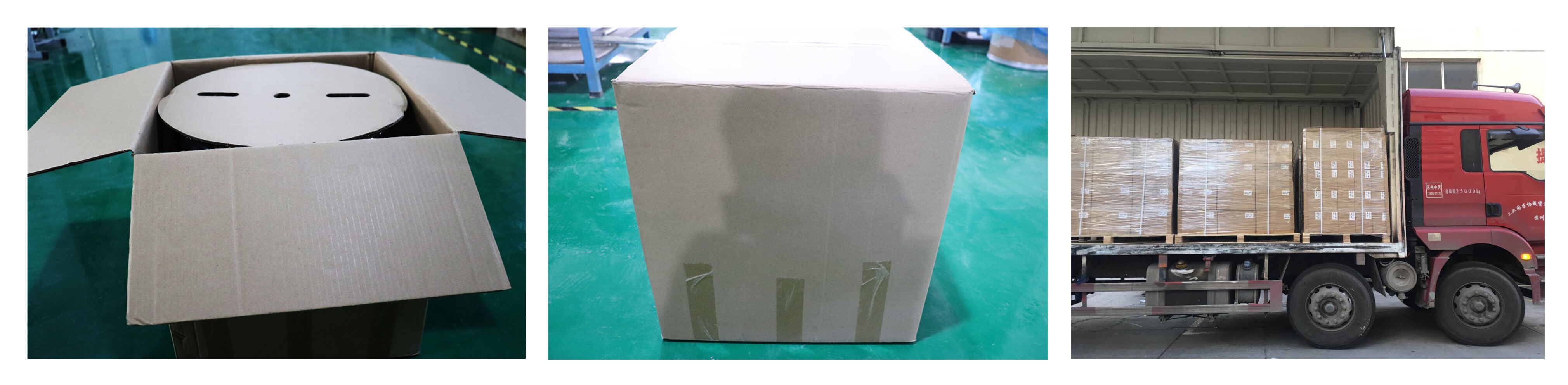

Packaging |

Normal: Plastic bag & Carton & Pallet

Special: Customized packing |

FAQQ 1. How long is the payment termA: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product ordersA: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packagingA: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your productsA: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you haveA1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk orderA1: We provide pre-production samples to all customers before mass production if needed.

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized serviceA: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements