* Excellent mechanical properties and extensibility

* Excellent thermal conductivity and aging resistance

* Low viscosity, self-leveling, excellent drilling ability

* Low modulus, low stress, good adhesion to both metals and plastics

Volsun

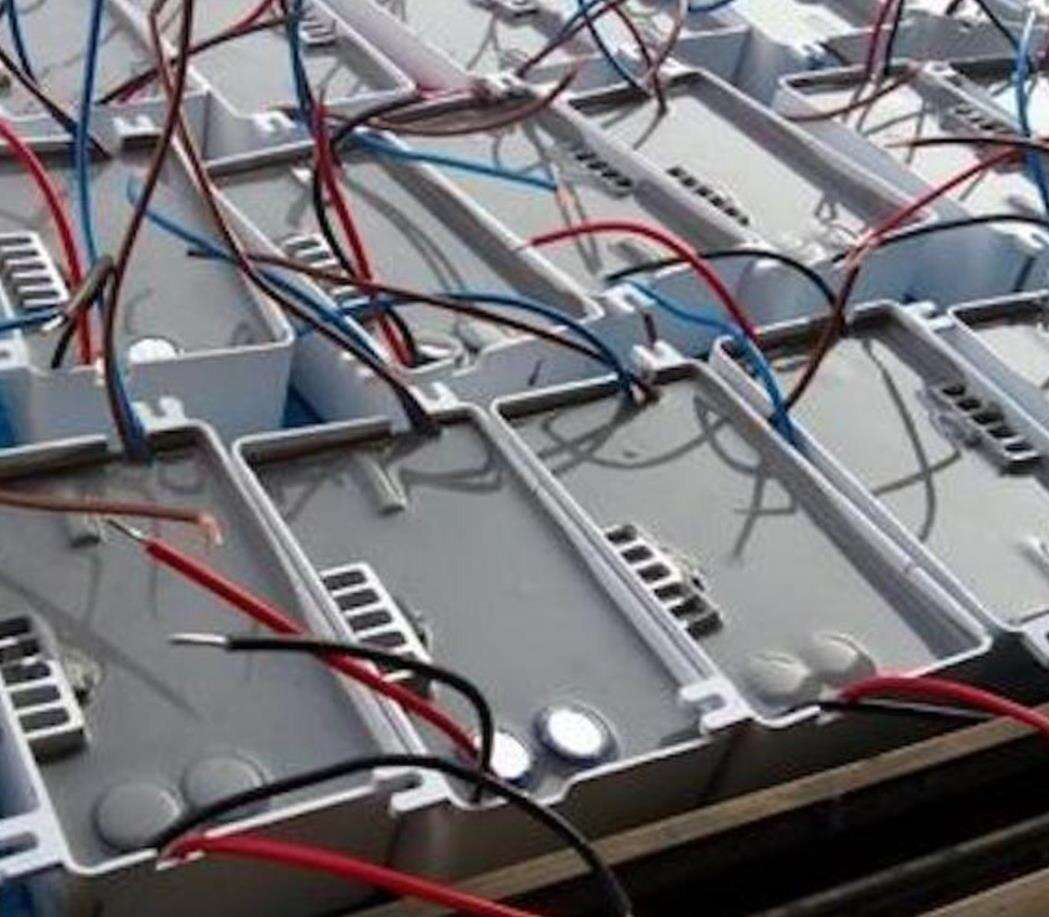

Proud to introduce its Two components PCB Pot Compound 1: 1 Silicone Electrical Potting Compound for LED Components. Volsun's innovative product is designed to provide superior protection for electronic components, including sensitive LED components, while also enhancing their performance.

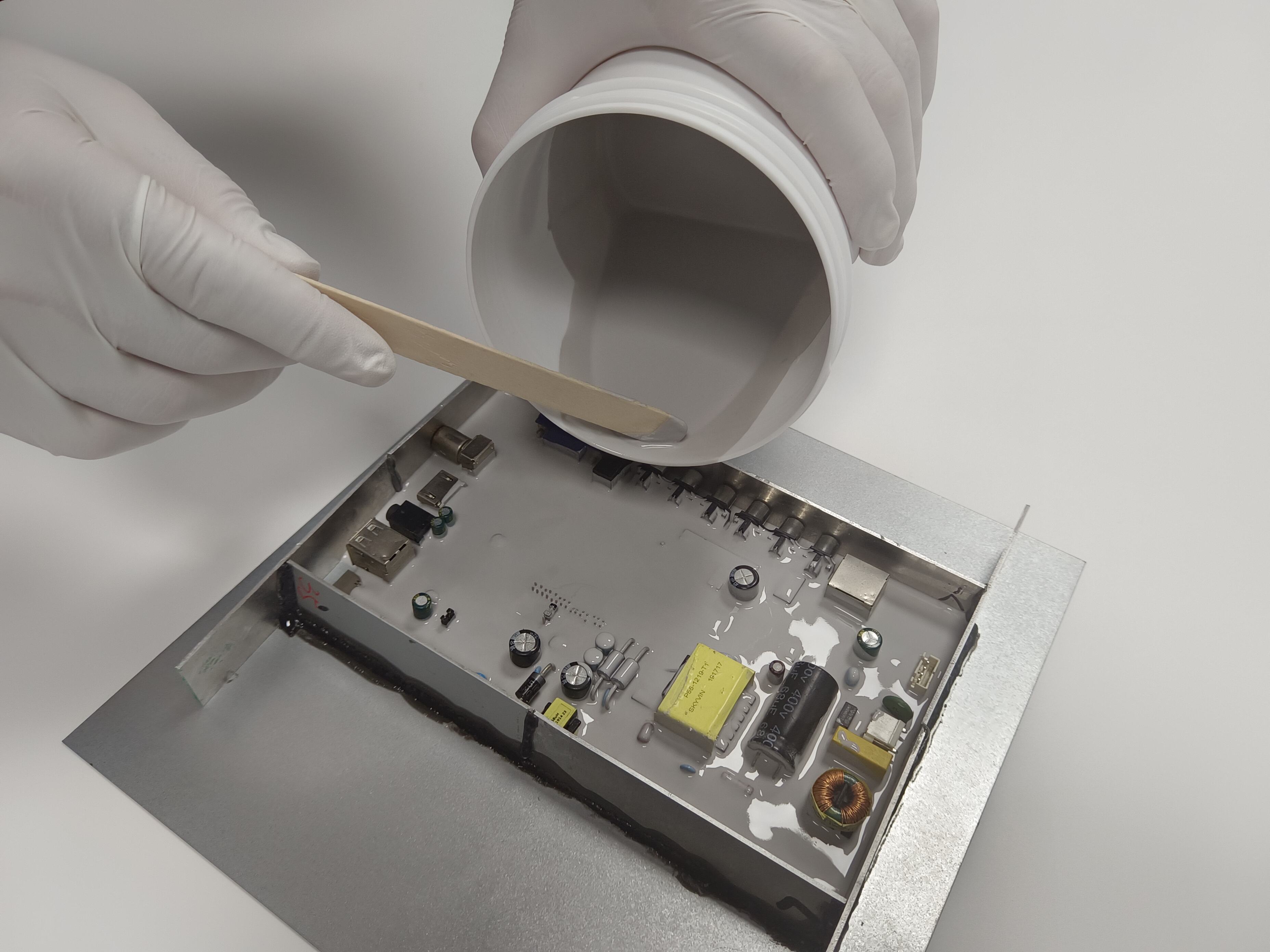

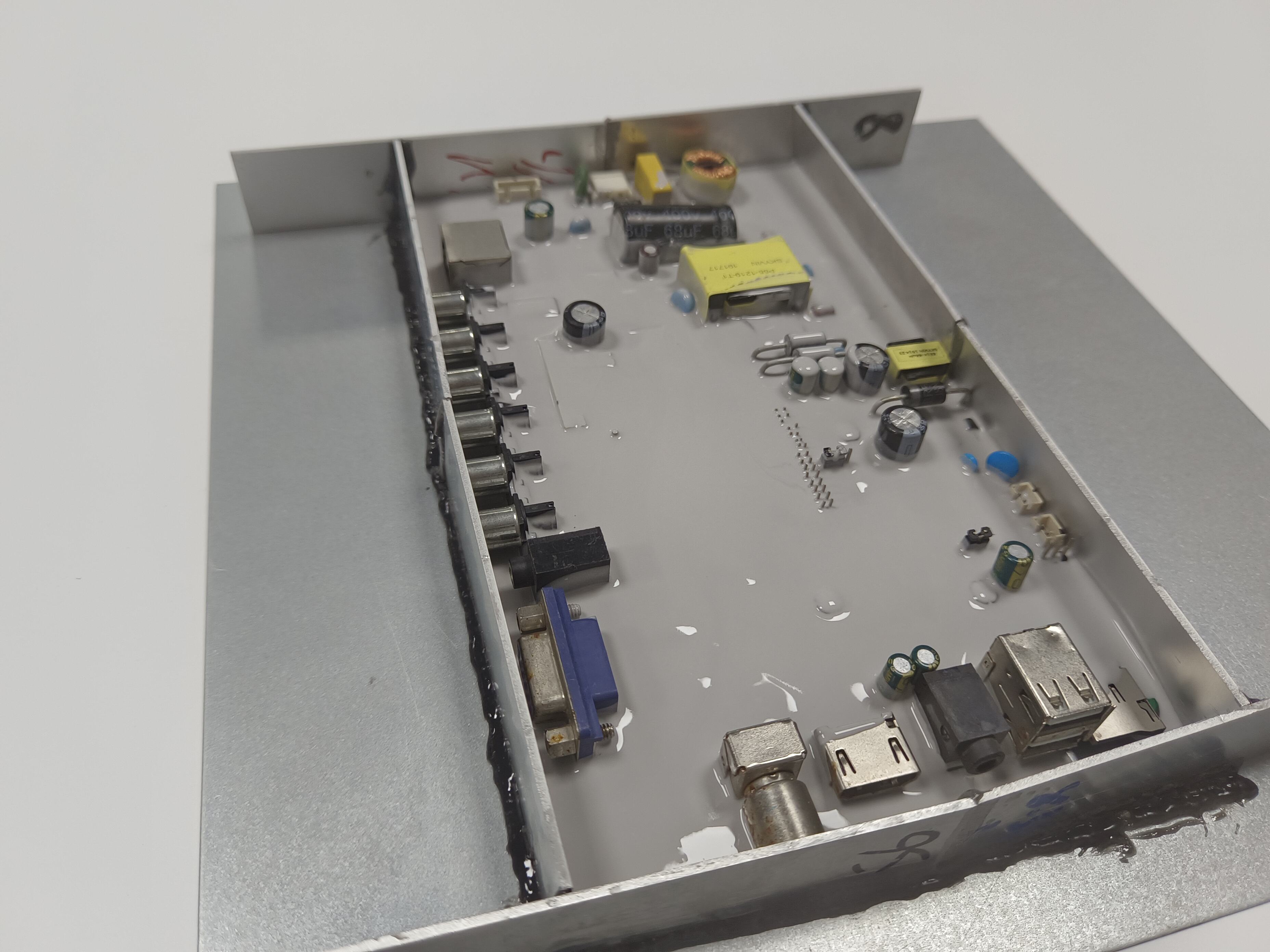

The Two components PCB Pot Compound 1: 1 Silicone Electrical Potting Compound is an excellent solution for those looking to improve the longevity and performance of their LED products. The compound is made up of two parts, which are mixed together to create a viscous, self-leveling liquid that can be easily applied to electronic components. Thanks to its excellent flowability, it is easy to fill complex shapes and hard to reach areas without any air pockets.

Moreover, this potting compound is fully waterproof, Volsun UV resistant, and has high dielectric strength, which improves its ability to protect electronic components from outside elements. Furthermore, the Two components PCB Pot Compound 1: 1 Silicone Electrical Potting Compound for LED Components is flexible and has excellent adhesion properties, ensuring that electronic components remain protected even after exposure to extreme temperatures, vibrations, and shocks.

Additionally, this Volsun product is designed to be eco-friendly and safe for human handling. Many of its competitors use harmful chemicals that are damaging to the environment, but this potting compound is free from solvents and toxins, ensuring that the environment is left unharmed and that consumers are safe from toxins.

Another huge selling point of the Two components PCB Pot Compound 1: 1 Silicone Electrical Potting Compound for LED Components is its ease of use. This product is designed to make potting components a convenient and stress-free task. The mixing ratio is straightforward, and the potting compound cures at room temperature.

Item |

Typical Data |

Test Method |

Mixing ratio |

1: 1 |

/ |

Color(After mixing) |

Grey |

Visual |

Viscosity (Component A) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (Component B) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (After mixing) @25℃ |

7000-9000cps |

ASTM D2196 |

Opening hours @25℃ |

≥60min |

/ |

Curing condition |

30min/50℃;20min/100℃ |

/ |

Thermal Conductivity |

2.0±0.2 W/m·k |

ASTM D5470 |

Hardness |

45±5 Shore A |

GB/T 531.1-2008 |

Density |

2.8±0.2 g/cm3 |

GB/T 1033.1-2008 |

Tensile strength |

>0.2MPa |

GB/T 528-2009 |

Elongation at break |

>10% |

GB/T 528-2009 |

Flame retardance |

V-0 |

UL94 |

Breakdown strength |

≥10 kV/mm |

GB/T 1695-2005 |

Volume resistivity |

≥ 1.0×1013 Ω·cm |

GB/T 1692-2008 |

Size |

Package |

VS-TP2001(1kg) |

Component A: 0.5kg; Component B: 0.5kg |

VS-TP2001(20kg) |

Component A: 10kg; Component B: 10kg |

VS-TP2001(40kg) |

Component A: 20kg; Component B: 20kg |

VS-TP2001(80kg) |

Component A: 40kg; Component B: 40kg |

VS-TP2001(100kg) |

Component A: 50kg; Component B: 50kg |

* In order to ensure the uniform distribution of fillers, components A and B must be stirred separately before mixing, so that each compounding agent is evenly mixed.

* After A and B are mixed, they will react and cure each other, so they need to be used up after mixing, and they cannot be used twice after mixing and curing.

* When pouring into the protective part, there should be no large debris or other contaminants in the protective part to avoid affecting the mutual adhesion of the material and the object

Copyright © Suzhou Volsun Electronics Technology Co., Ltd All Rights Reserved.