* Continuous operating temperature:-40℃~+200℃

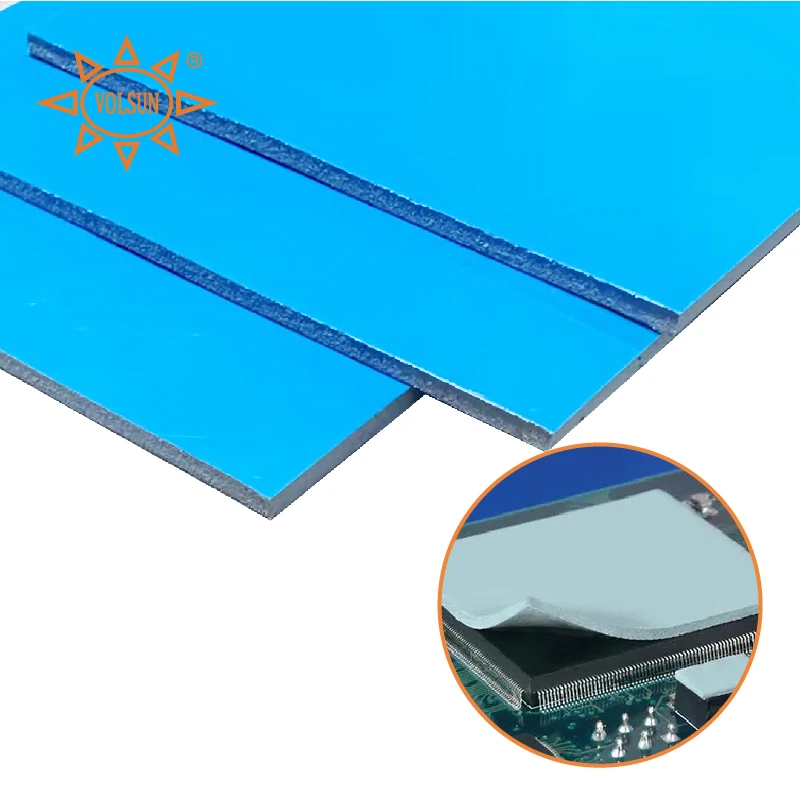

* High thermal conductivity, low thermal resistance

* Excellent surface wettability and resilience

* Excellent flame retardancy

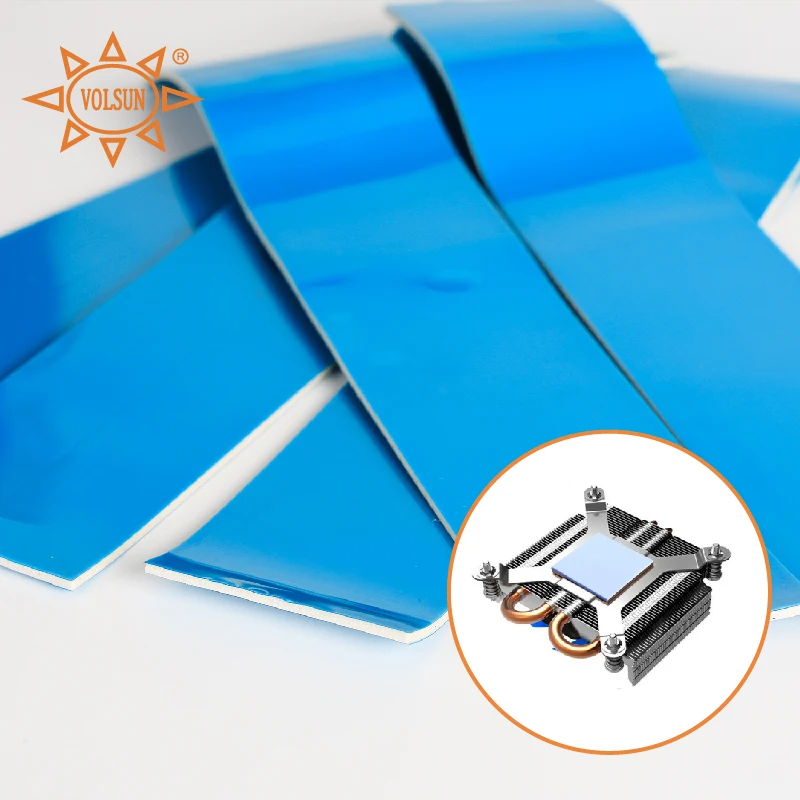

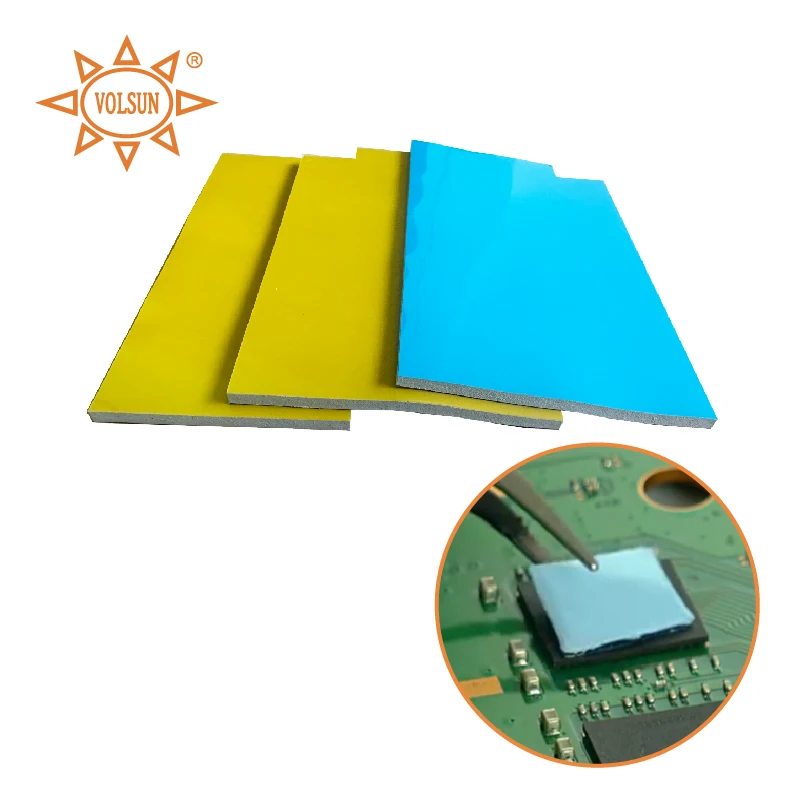

* Multiple thickness selection, wide application range

* High thermal conductivity, low thermal resistance

* Excellent surface wettability and resilience

* Excellent flame retardancy

* Multiple thickness selection, wide application range

* Environmental protection standard: RoHS, REACH

Support customization, ODM & OEM available