* Excellent mechanical properties and extensibility

* Excellent thermal conductivity and aging resistance

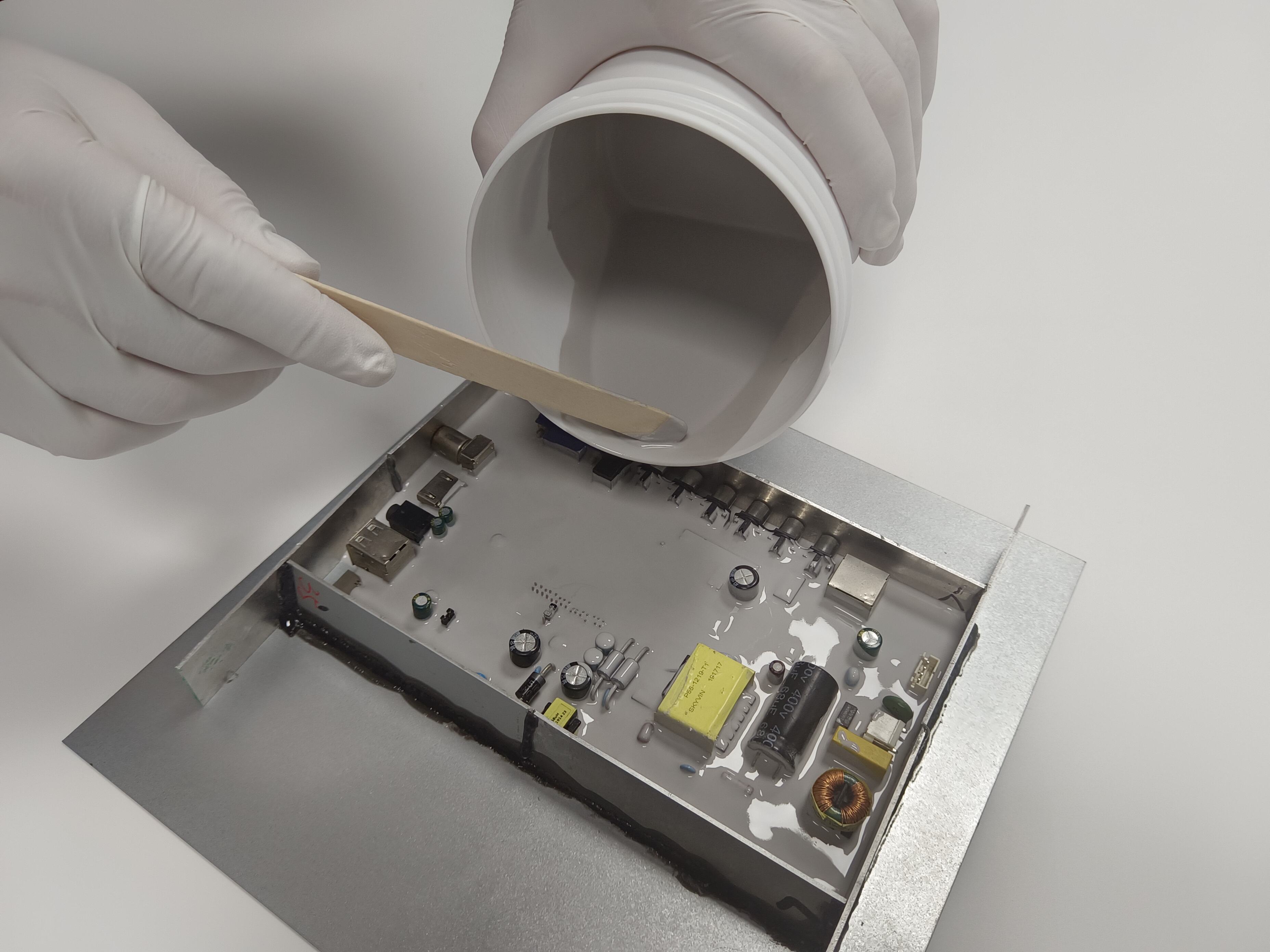

* Low viscosity, self-leveling, excellent drilling ability

* Low modulus, low stress, good adhesion to both metals and plastics

Volsun

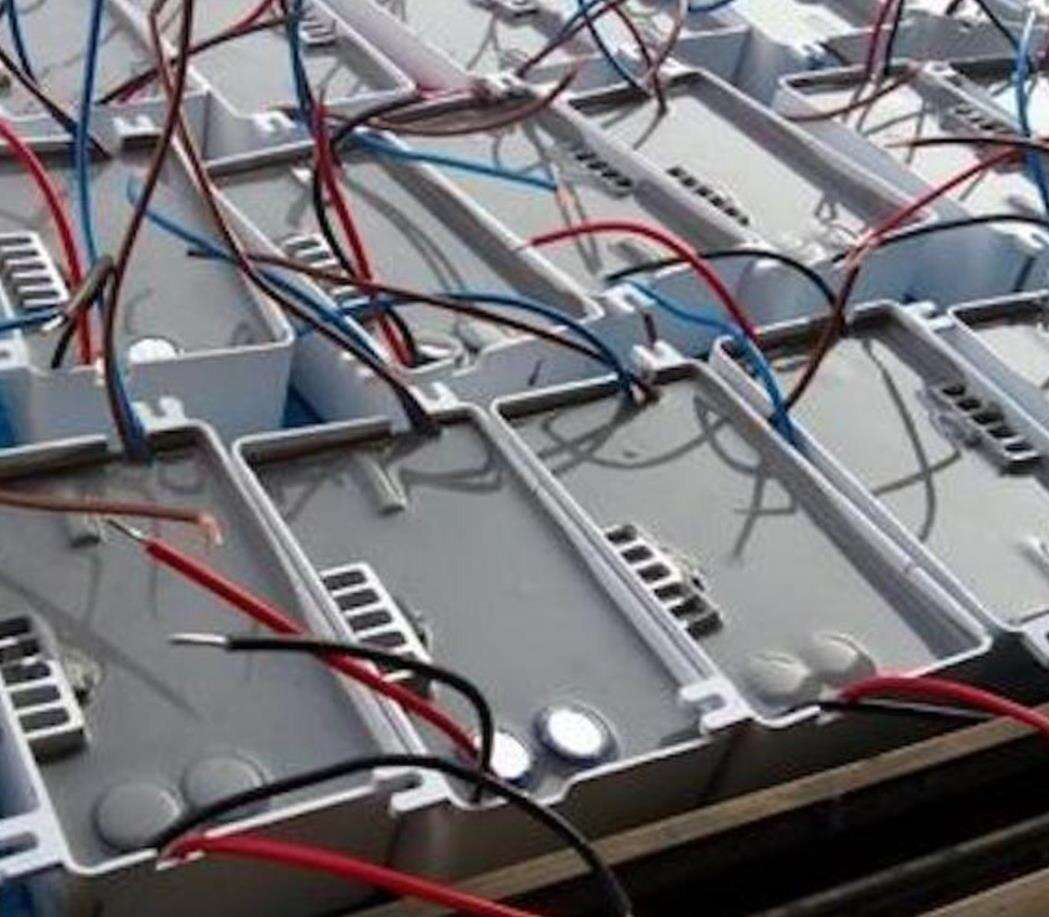

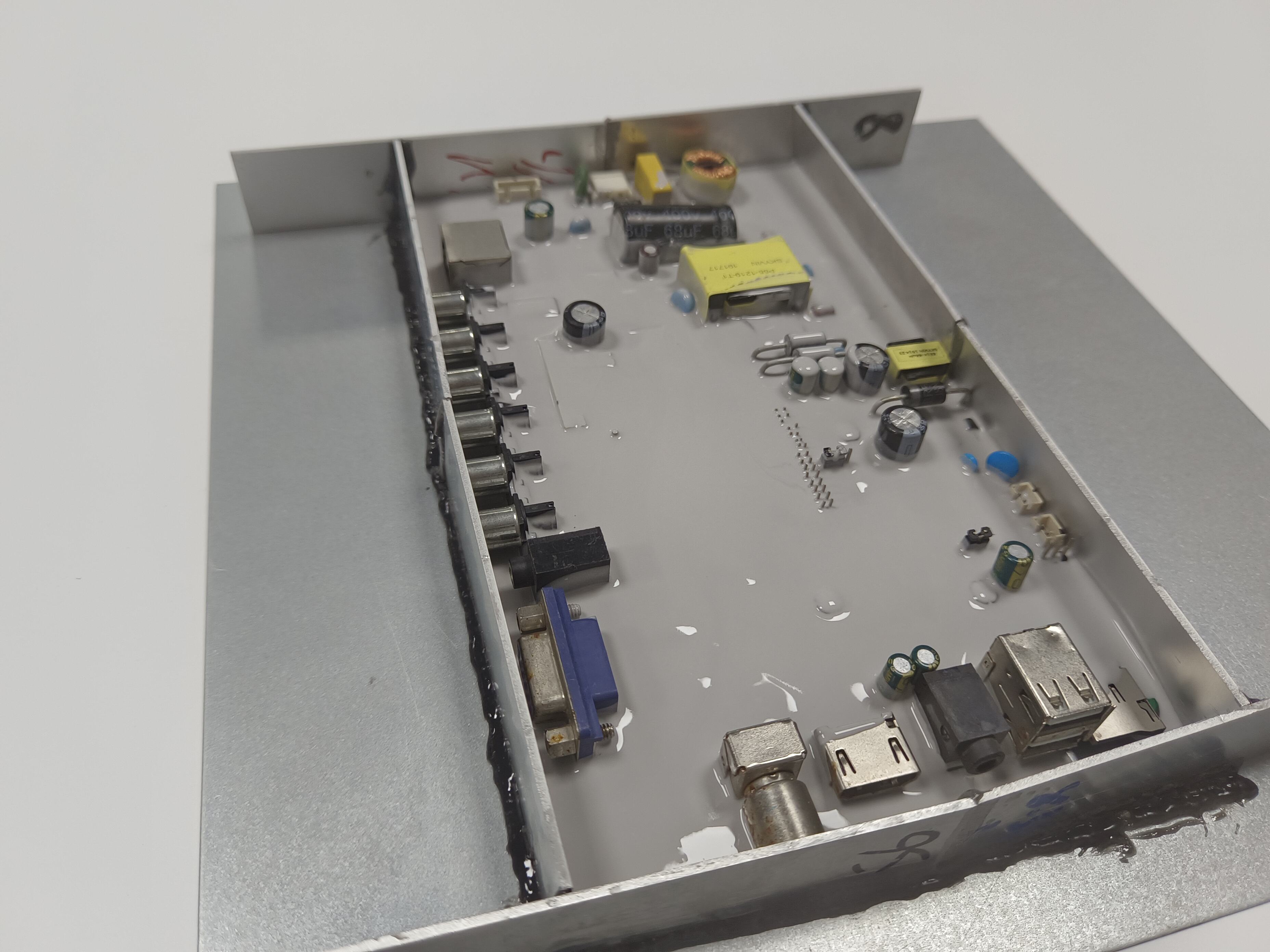

Potting Compound is a high-quality, silicone-based material designed to protect electronics from harsh environmental conditions. It is ideal for various applications, including electrical and electronic insulation, waterproofing, and encapsulation.

This Potting Compound is made with a unique formulation of high-performance Volsun silicone, ensuring it offers excellent insulation and protection against moisture, heat, and chemicals. It is specially designed to provide superior adhesion to electronic components and PCBs.

Volsun Potting Compound is easy to use since it doesn't require any additional equipment to apply. It cures quickly and has a long term stability, meaning it can last for an extended period without any replacement.

One of the significant advantages of Volsun Potting Compound is its ability to withstand harsh environmental conditions, such as extreme temperatures, UV radiation, and even corrosive substances. This feature makes it ideal for applications that require protection against harsh outdoor environments.

The Potting Compound is also highly resistant to mechanical stress, making it ideal for use in high-vibration environments. It provides excellent encapsulation and protection against physical damage due to its softness.

Unlike other Potting Compounds, Volsun Potting Compound is non-toxic and safe to use. It's also non-flammable, which ensures it offers protection against fire hazards.

The product is available in different colors and viscosities, allowing users to choose the ideal variant depending on the application. The Potting Compound is also flexible, making it suitable for applications that require flexibility.

Volsun Potting Compound is an excellent alternative to traditional Potting Compounds since it offers superior performance and durability. It can be used on various electronic devices, including LED lighting, sensors, and even medical devices.

Item |

Typical Data |

Test Method |

Mixing ratio |

1: 1 |

/ |

Color(After mixing) |

Grey |

Visual |

Viscosity (Component A) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (Component B) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (After mixing) @25℃ |

7000-9000cps |

ASTM D2196 |

Opening hours @25℃ |

≥60min |

/ |

Curing condition |

30min/50℃;20min/100℃ |

/ |

Thermal Conductivity |

2.0±0.2 W/m·k |

ASTM D5470 |

Hardness |

45±5 Shore A |

GB/T 531.1-2008 |

Density |

2.8±0.2 g/cm3 |

GB/T 1033.1-2008 |

Tensile strength |

>0.2MPa |

GB/T 528-2009 |

Elongation at break |

>10% |

GB/T 528-2009 |

Flame retardance |

V-0 |

UL94 |

Breakdown strength |

≥10 kV/mm |

GB/T 1695-2005 |

Volume resistivity |

≥ 1.0×1013 Ω·cm |

GB/T 1692-2008 |

Size |

Package |

VS-TP2001(1kg |

Component A: 0.5kg; Component B: 0.5kg |

VS-TP2001(20kg) |

Component A: 10kg; Component B: 10kg |

VS-TP2001(40kg) |

Component A: 20kg; Component B: 20kg |

VS-TP2001(80kg) |

Component A: 40kg; Component B: 40kg |

VS-TP2001(100kg) |

Component A: 50kg; Component B: 50kg |

* This product should not be in the mouth and eyes. If it accidentally enters the mouth and eyes, rinse it with water in time or go to the hospital for medical treatment.

* If need high thermal conductivity, vacuum degassing is required before pouring

* In low temperature environment, the curing time will be extended accordingly

Copyright © Suzhou Volsun Electronics Technology Co., Ltd All Rights Reserved.