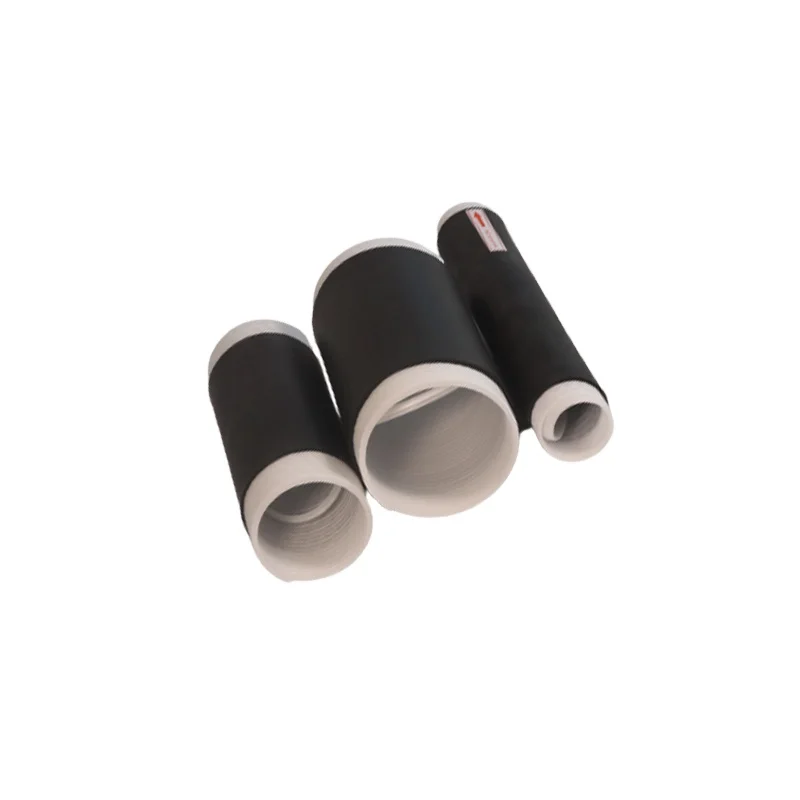

Looking for a reliable, high-quality cold shrink tube that can withstand extreme UV exposure? Look no further than the Volsun’s 8420 series EPDM cold shrink tube! Made from top-of-the-line EPDM rubber material, this hot-selling tubing is the perfect choice for a wide range of applications.

With its exceptional UV resistance, the Volsun’s 8420 series cold shrink tube offers unparalleled protection against the damaging effects of the sun's rays. Unlike other types of tubing that can deteriorate quickly when exposed to UV light, this tubing will stay strong and resilient even in the most challenging environments. Whether you're using it in outdoor equipment, solar panels, or other applications, you can trust the Volsun’s 8420 series to provide the protection and durability you need.

What sets the Volsun’s 8420 series apart from other cold shrink tubes on the market? For one thing, it's incredibly easy to install. The tubes come pre-stretched over a removable core, making it simple to fit them over cable connections or other parts. Once in place, the tubes will naturally shrink to create a tight, secure seal around the connection. This eliminates the need for messy adhesives or complicated installation processes, saving you time and hassle.

Of course, easy installation wouldn't be worth much if the tubing didn't work. Thankfully, the Volsun’s 8420 series delivers top-notch performance as well. In addition to its exceptional UV resistance, the tubing is also highly resistant to moisture, corrosion, and other environmental factors. This ensures that your connections will stay secure and protected even in harsh conditions.

When it comes to cold shrink tubing, you don't want to take any chances. That's why you need a product you can trust – and that's exactly what you'll get with the Volsun’s 8420 series. This high-quality, high-performance tubing has earned a reputation as one of the best options on the market, thanks to its exceptional durability, easy installation, and top-notch UV resistance. So why settle for anything less? Choose the Volsun’s 8420 series EPDM cold shrink tube and enjoy the peace of mind that comes with using the best

RUBLS-EPDM a series of open-ended, tubular rubber sleeves, which are factory expanded and assembled onto a removable core. They are supplied for field installation in this pre-stretched condition. The core is removed after the tube has been positioned for installation over an in line connection, terminal lug, etc., allowing the tube to shrink and form a waterproof seal. The insulation tube is made of EPDM rubber, which contains no chlorides or sulphurs. Various diameter sizes will cover a range of 1000 volt cables, copper and aluminum conductors

Features:

• Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

• More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

• Simultaneously expands and shrinks with workpieces without clearances, seals tight in harsh environment

• Stably sealing the workpieces in windy environment

• Well suited for cable less than 1KV

• Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure

• Simple, safe installation, requires no tools or special training. No torches or heat work required

• Diameter shrinkage:±50%

• Sealing class IP68

|

|

Min Cable Outer Diameter mm |

Max Cable Outer Diameter mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions for over 18 years

Quality is our culture. Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc. And we have gained some advanced titles such as Jiangsu famous scientific and technical corporation, China new high-tech enterprise etc. have independent intellectual property rights, 88 patents and 97 product certifications

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

Supply capability |

1,000,000 pieces per month |

Lead time |

Usually 2-3 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet

Special: Customized packing

|

Q 1. How long is the payment termA: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product ordersA: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packagingA: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your productsA: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you haveA1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk orderA1: We provide pre-production samples to all customers before mass production if needed.

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized serviceA: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements