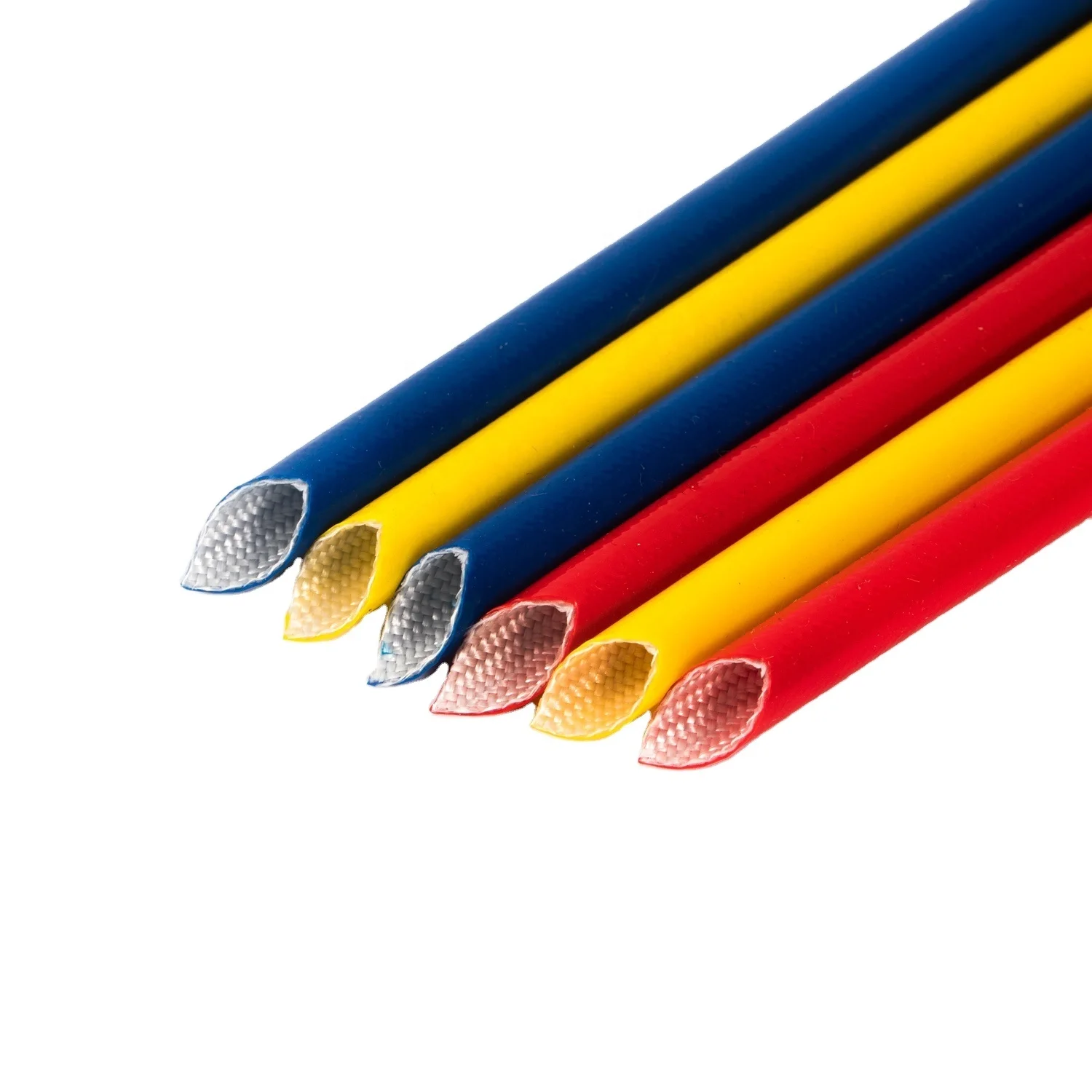

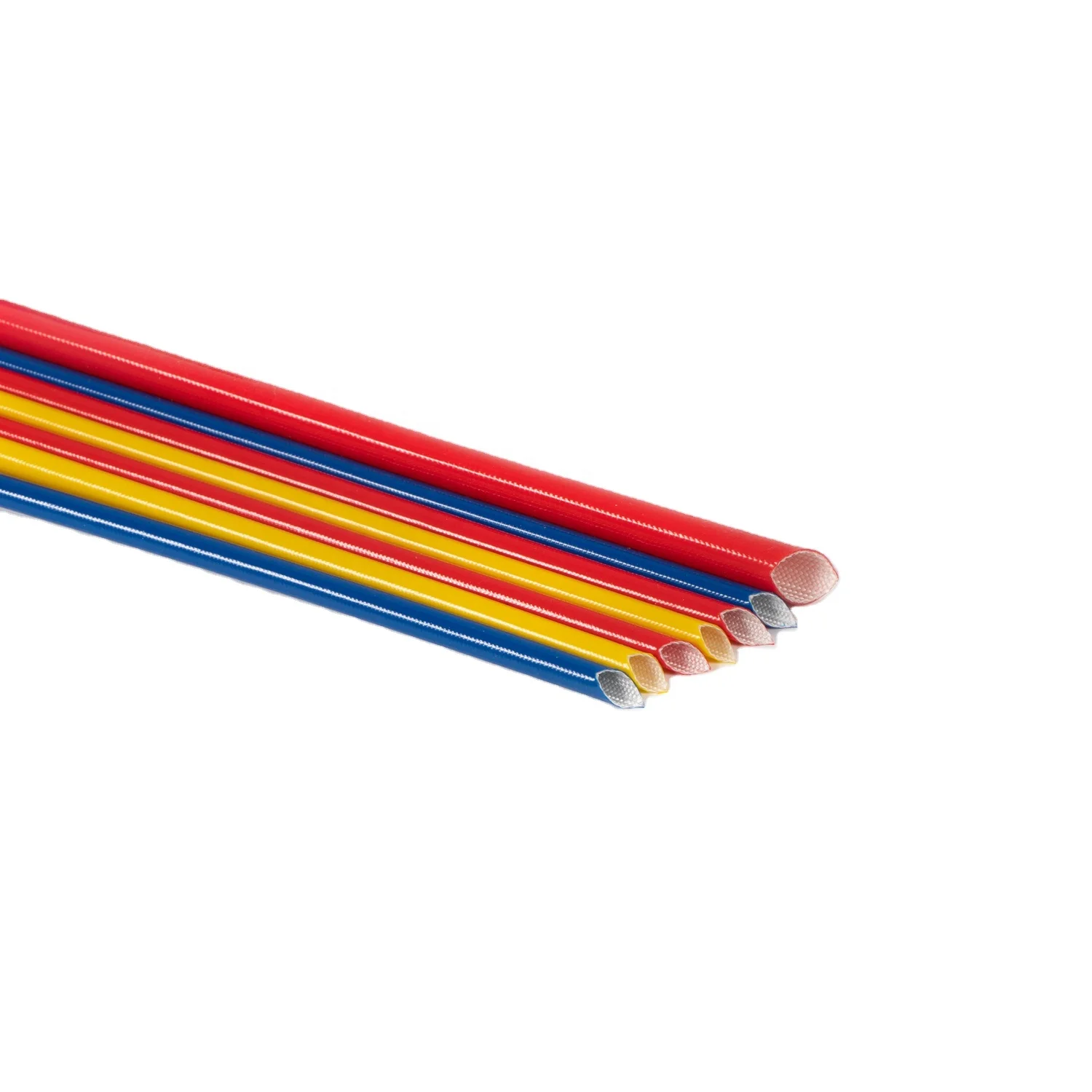

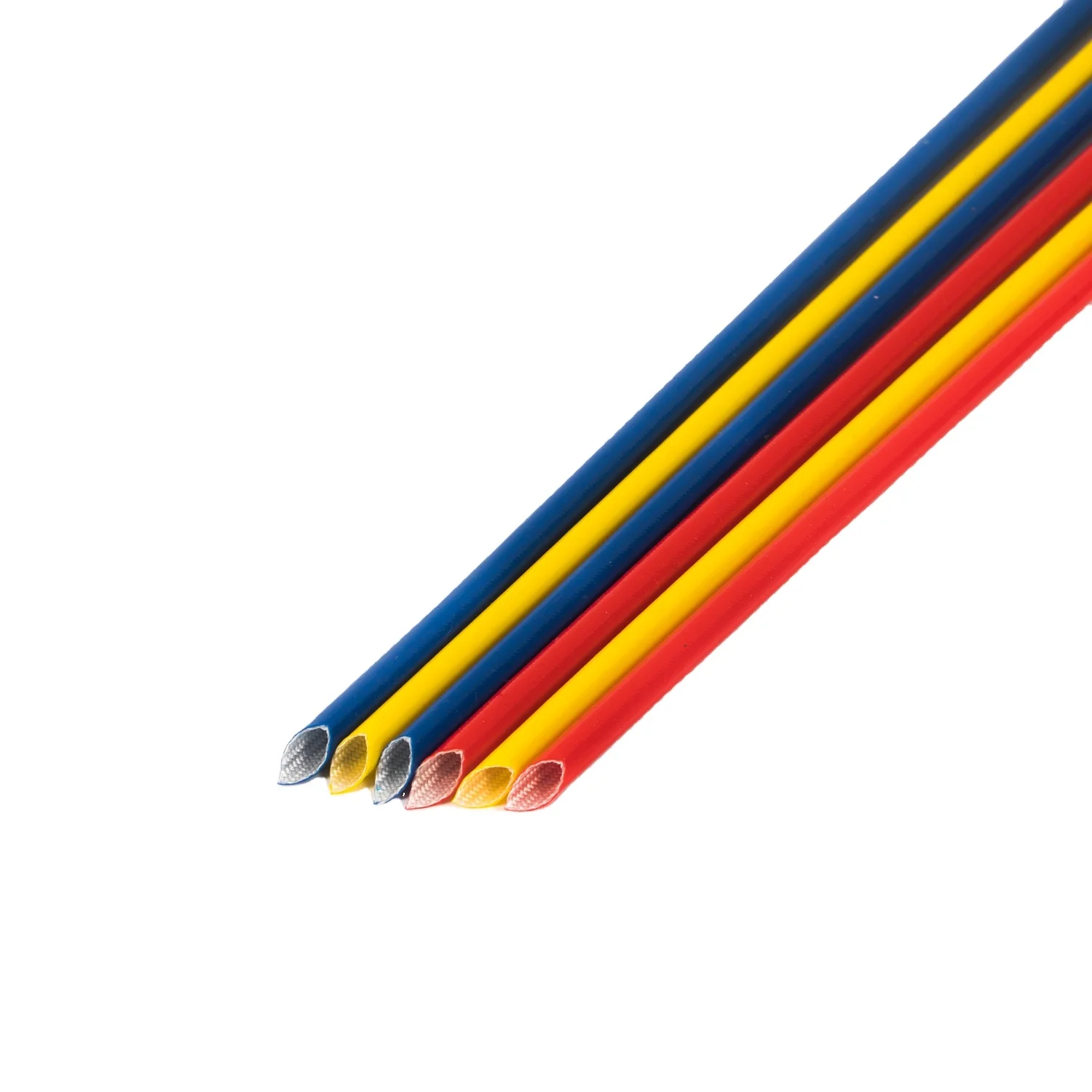

UL Certified Fiberglass Sleeving 4KV Silicone Coated Fiberglass Sleeve For Cable Wire Harness

Description

Volsun has introduced a reliable and durable solution for cable wire protection – White Color Silicone Coated Fiberglass Sleeve. It is designed to offer optimal protection for wire cable installation and equipment protection. The 4KV rated sleeve is made from high-quality fiberglass material and coated with silicone for increased strength and durability.

The White Color Silicone Coated Fiberglass Sleeve by Volsun is ideal for use in high-temperature environments, providing resistance to heat, flames, and abrasion. The sleeve insulates the cable wires from external damage, ensuring safety and smooth operation. The white color silicone coating provides a sleek and professional finish to the product, making it a suitable choice for any industrial or commercial application.

The Volsun’s White Color Silicone Coated Fiberglass Sleeve is easy to install, with a seamless inner diameter that provides a snug fit for the wires. The sleeve is also flexible, allowing for easy bending and manipulation without damaging the cable. The silicone coating ensures that the sleeve remains in place throughout its lifespan, providing reliable protection to the cable wire.

In addition to its excellent thermal and mechanical properties, the Volsun’s White Color Silicone Coated Fiberglass Sleeve also has excellent electrical insulation properties. The sleeve insulates the wire from any external electrical interference, ensuring that the signal is transmitted without disruption. This feature makes it a great choice for electronic applications that require high levels of signal purity.

The Volsun’s White Color Silicone Coated Fiberglass Sleeve is available in different sizes to fit varying cable diameters, making it adaptable to different applications. The product comes in convenient rolls for easy storage and transportation, allowing users to cut the sleeve to specific lengths when required. The 4KV rating of the sleeve makes it ideal for use in low to medium voltage applications

Items |

Technical Parameters |

Reference Standard |

Appearance |

No glue leakage, cracking, etc |

GB/T 7113.1-2014 |

Coating hydrolysis |

No coating displacement, adhesion, etc |

GB/T 7113.2 |

Cold bending test |

-40℃,4h,No cracks, coating peeling and delamination |

IEC60684 |

Temperature |

-40℃~200℃ |

UL1441 |

Flame retardant rating |

HB |

UL94 |

Breakdown voltage |

Reference standard |

GB/T 1408-2016 |

Heat Resistance |

250℃±5, 24h, No droplets, no flow marks, no cracking |

JB/T 7093 2015 |

Dimensions

I.D. mm |

Wall thickness mm |

Wall Thickness(mm) |

Package |

|||||||

Size |

Tolerance |

1500V |

2500V |

4000V |

7000V |

M/Roll |

||||

Φ2.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ3.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ4.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ5.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ6.0 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ7.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ8.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ9.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ10.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ12.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ13.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ14.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ15.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

We don't list all sizes here, other sizes are available on request

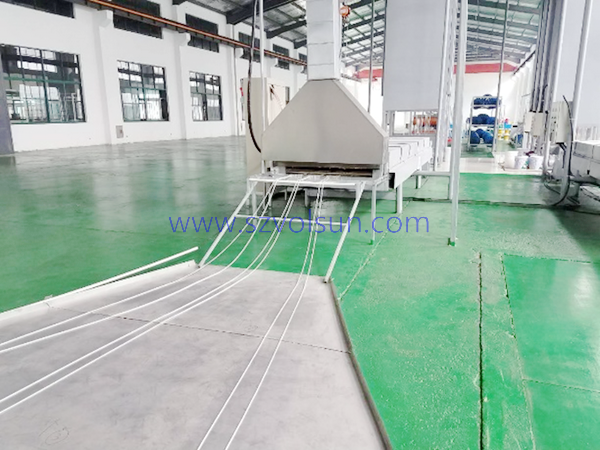

Company Show

Up to now, Volsun cooperated with customers from 88 countries, we offer suitable sealing, waterproof solutions for some well-know enterprises in communication, Automobile, Power industry etc

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

MOQ |

100M |

Supply capability |

1,000,000 mts per month |

Lead time |

Usually 2-3 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet Special: Customized packing |

Certificate

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product ordersA: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packagingA: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your productsA: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you haveA1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk orderA1: We provide pre-production samples to all customers before mass production if needed.

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized serviceA: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements