Description

Volsun

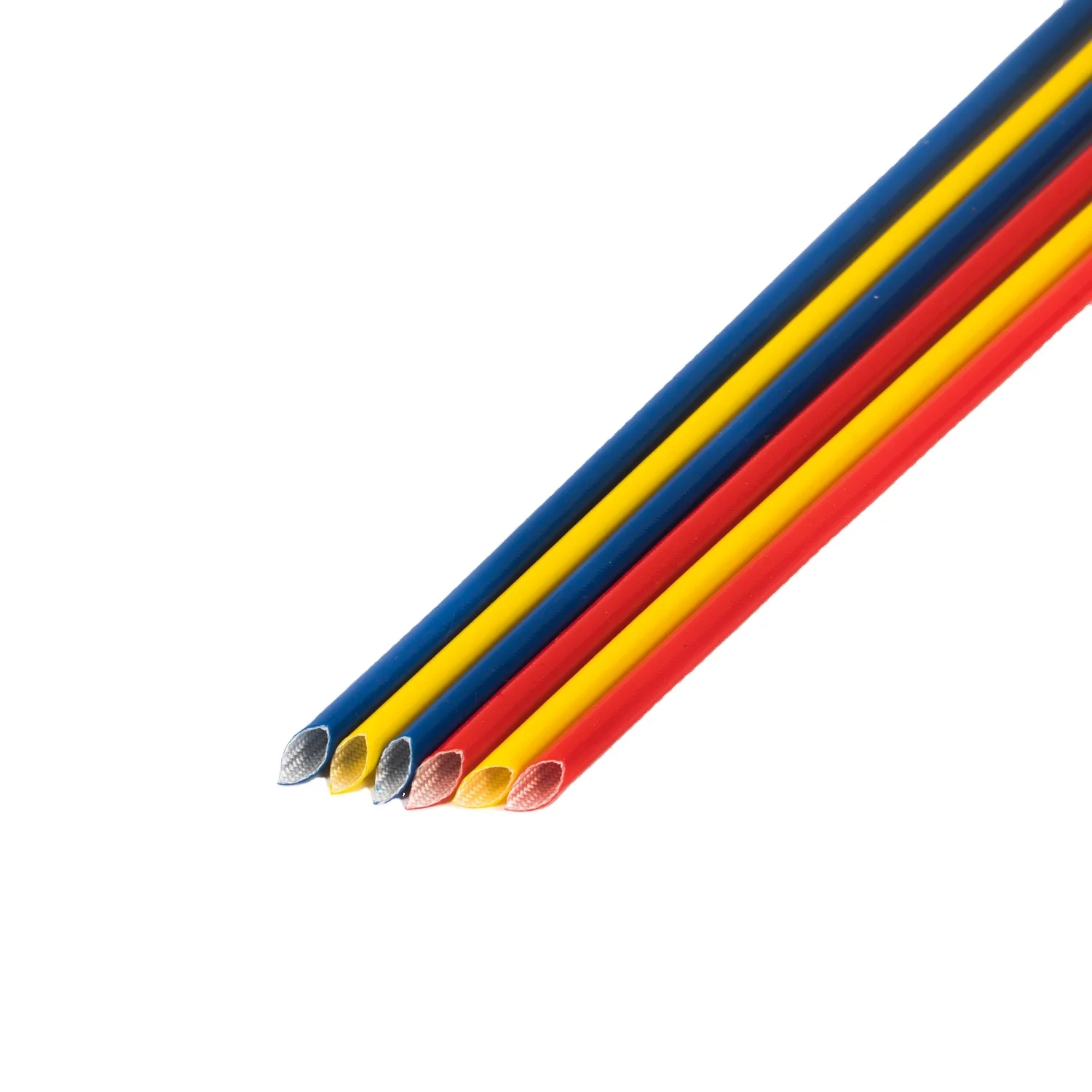

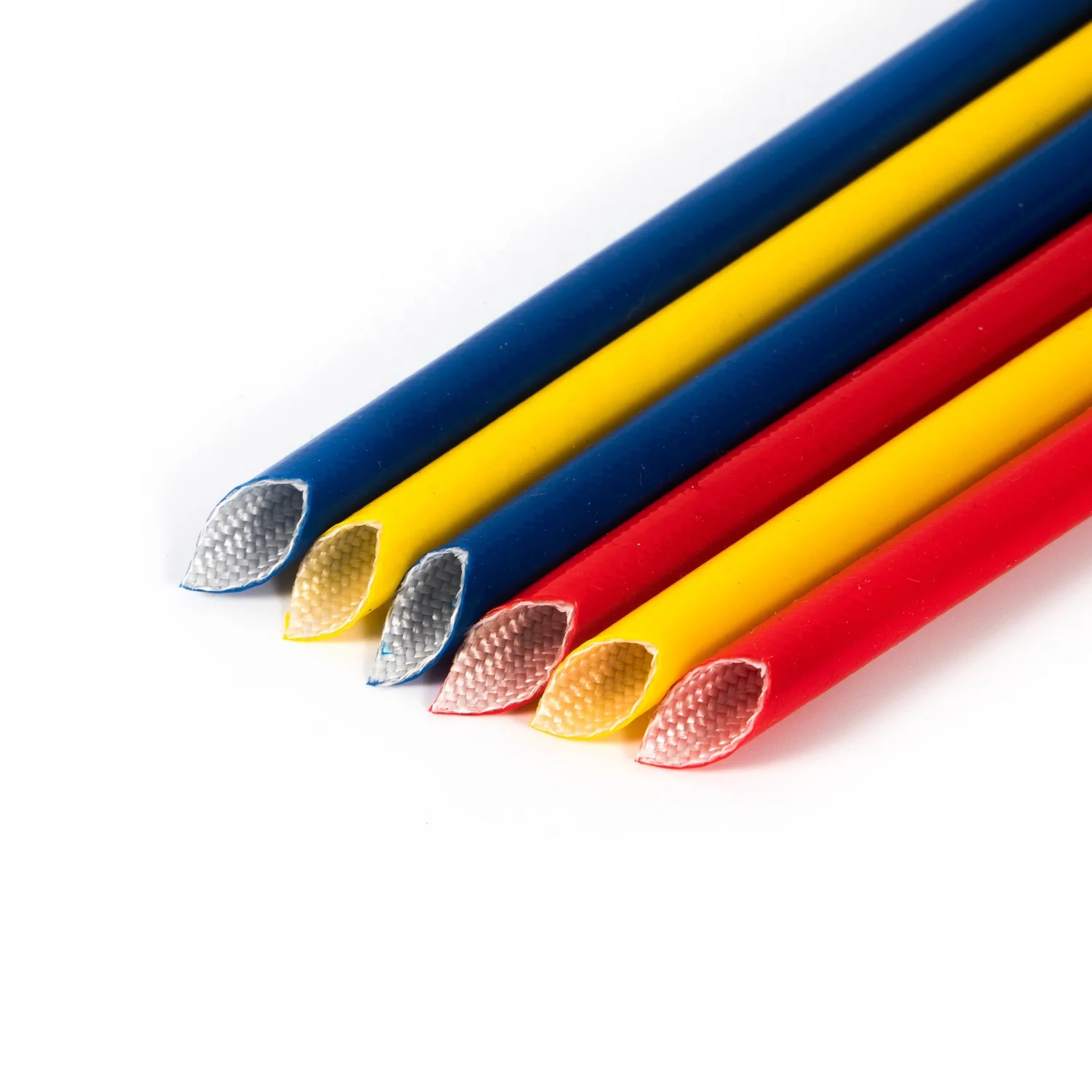

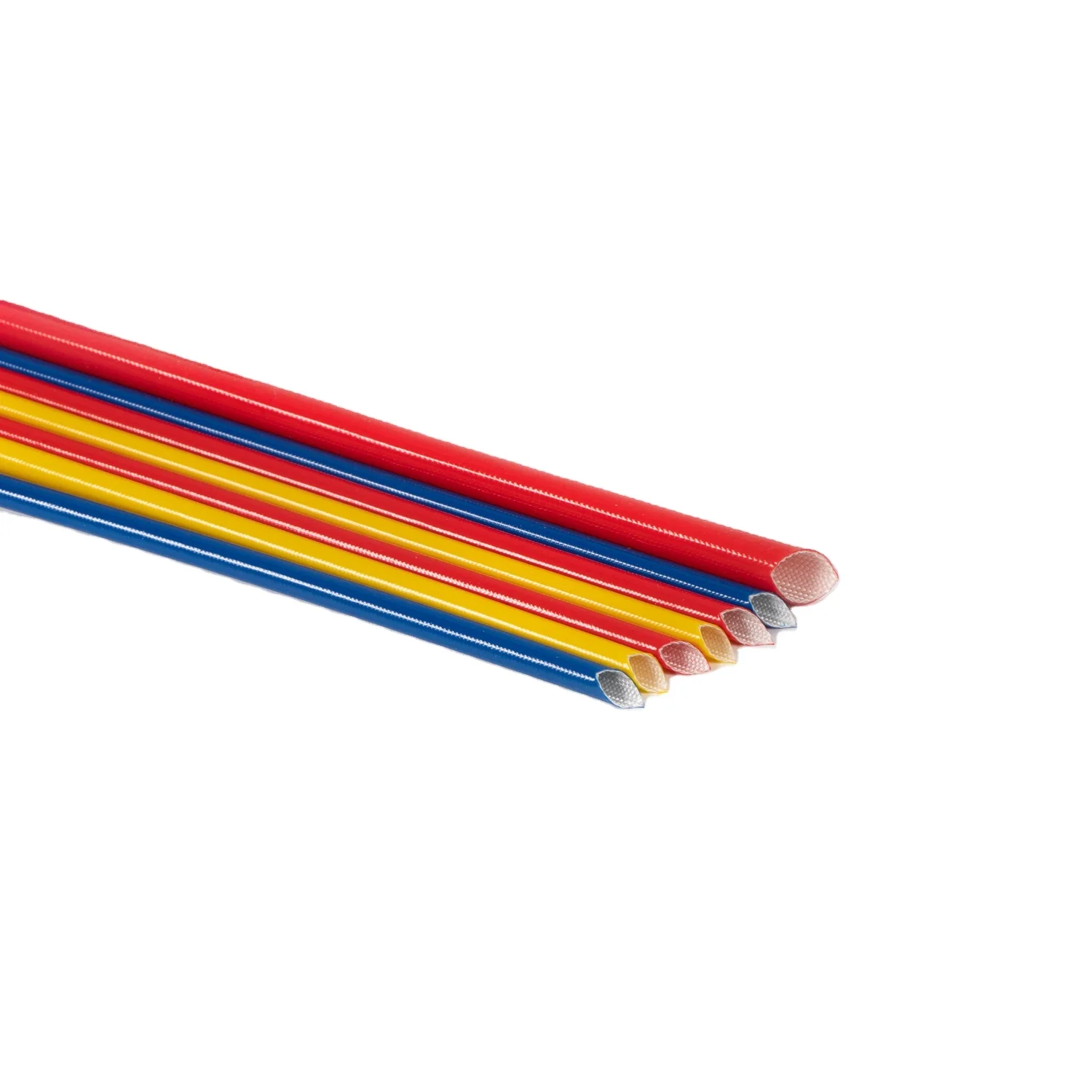

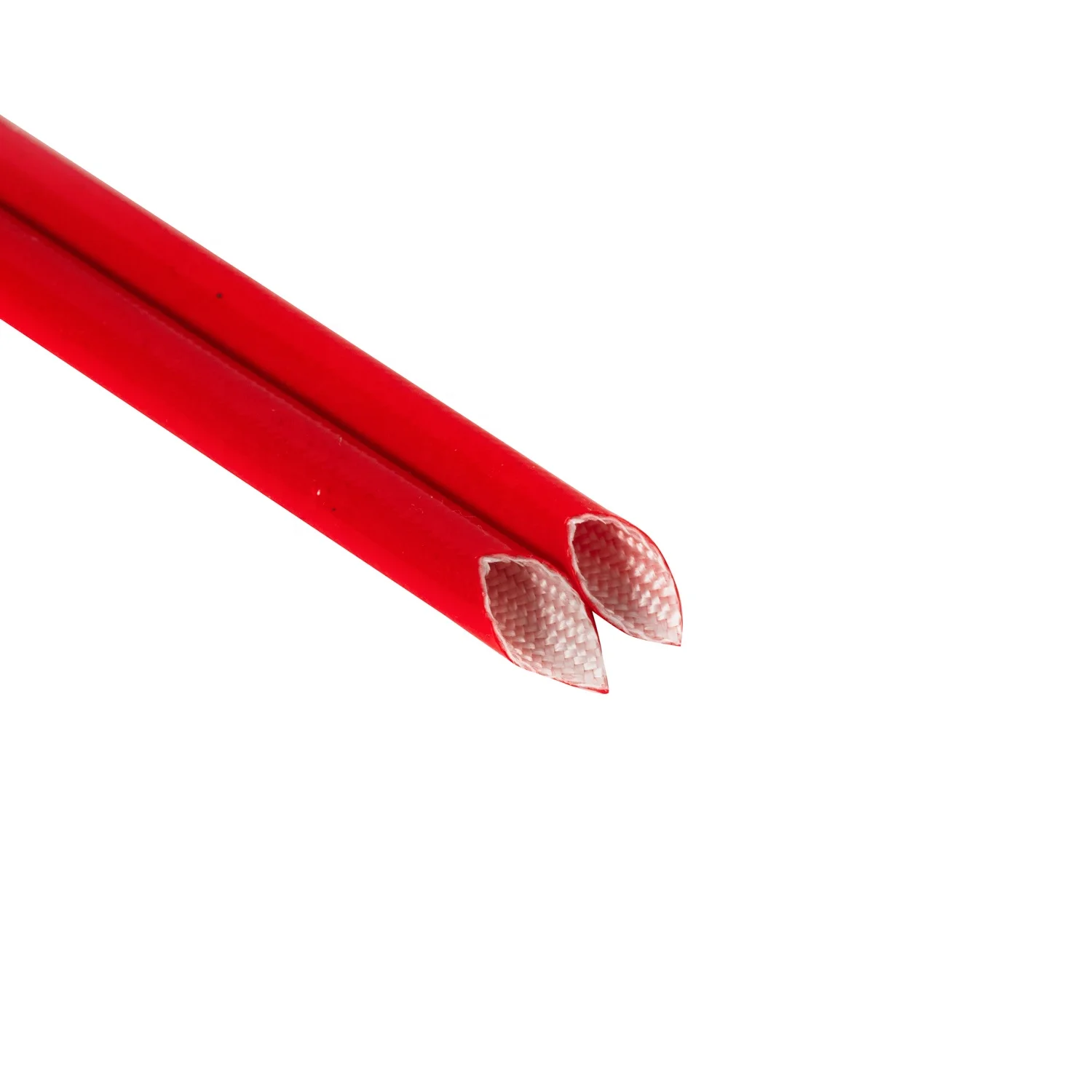

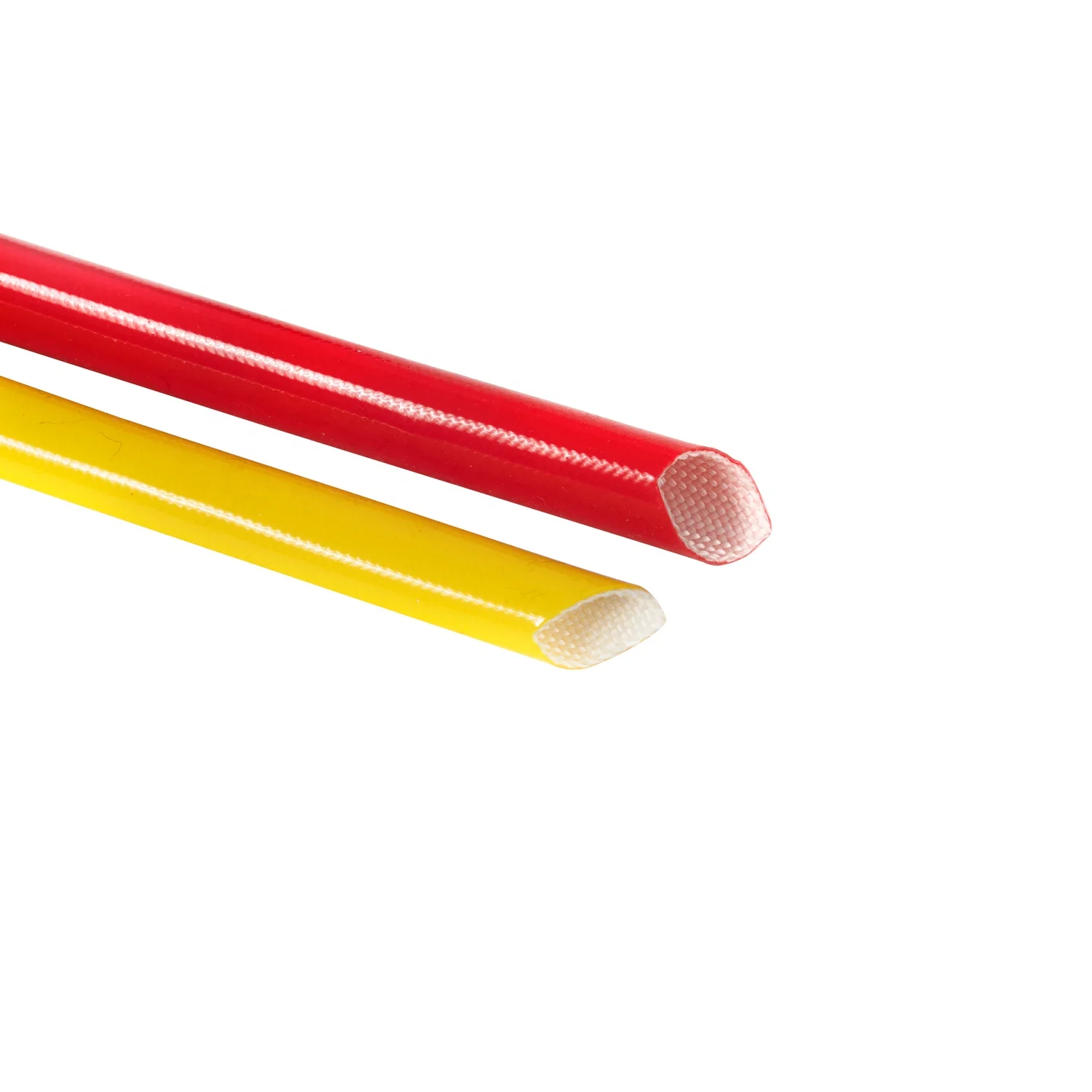

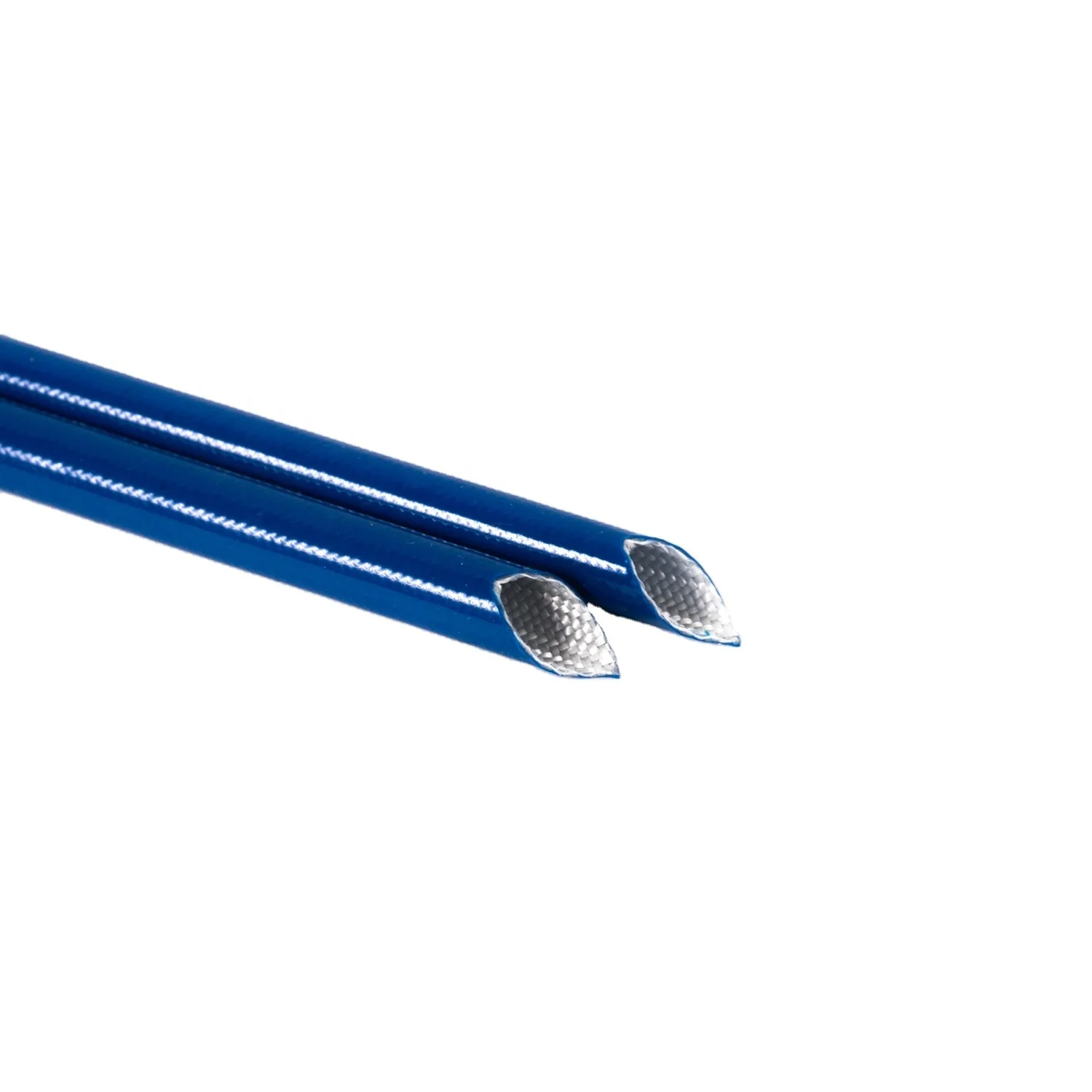

The 4KV UL certificated silicone rubber fiberglass sleeve silicone fiberglass sleeving is an excellent product that offers superior protection against damage caused by high temperatures and electrical currents. Made from durable materials, this silicone rubber fiberglass sleeve is designed to withstand harsh environments, making it an ideal choice for various applications.

This product comes in a range of sizes and is perfect for use in electrical and electronic equipment that requires reliable insulation. With a high dielectric strength, it can withstand voltage of up to 4KV, which makes it ideal for use in transformer and motor winding applications. The sleeve also has excellent thermal resistance, allowing it to withstand temperatures ranging from -70°C to 200°C.

The Volsun 4KV UL certificated silicone rubber fiberglass sleeve silicone fiberglass sleeving is easy to install and is reusable, making it an economical option for your business. This Volsun silicone rubber fiberglass sleeve is also highly flexible, which allows it to fit snugly around cables and other objects, protecting them from damage caused by abrasion and other environmental factors.

This product has been certified to meet UL requirements and is rated for use in a variety of applications such as wire and cable harnessing, electronic and electrical component insulation, and motor lead insulation. The Volsun 4KV UL certificated silicone rubber fiberglass sleeve silicone fiberglass sleeving is also halogen-free, making it a safe option for use in sensitive areas.

4KV UL certificated silicone rubber fiberglass sleeve silicone fiberglass sleeving

Items |

Technical Parameters |

Reference Standard |

Appearance |

No glue leakage, cracking, etc |

GB/T 7113.1-2014 |

Coating hydrolysis |

No coating displacement, adhesion, etc |

GB/T 7113.2 |

Cold bending test |

-40℃,4h,No cracks, coating peeling and delamination |

IEC60684 |

Temperature |

-40℃~200℃ |

UL1441 |

Flame retardant rating |

HB |

UL94 |

Breakdown voltage |

Reference standard |

GB/T 1408-2016 |

Heat Resistance |

250℃±5, 24h, No droplets, no flow marks, no cracking |

JB/T 7093 2015 |

Dimensions

I. D. (mm) |

Wall thickness(mm) |

Wall Thickness(mm) |

Package |

|||||||

Size |

Tolerance |

1500V |

2500V |

4000V |

7000V |

M/Roll |

||||

Φ2.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ2.5 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ3.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ3.5 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ4.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ4.5 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ5.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ5.5 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ6.0 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ7.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ8.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ9.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ10.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ11.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ12.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ13.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ14.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ15.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

We don't list all sizes here. Diameter 16mm-25mm can also produce

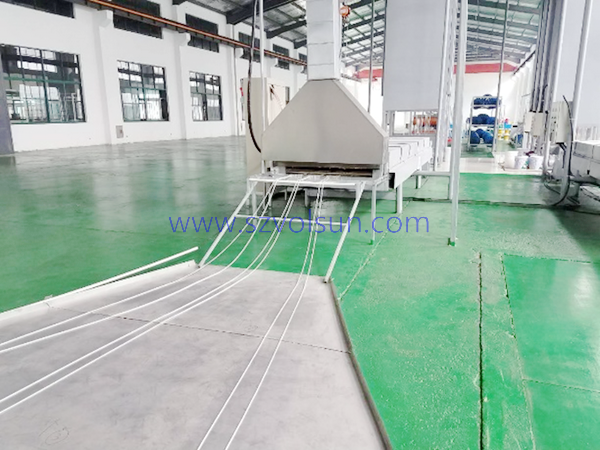

Company Show

Packing & Delivery

Certificate

Abroad Exhibition