Volsun

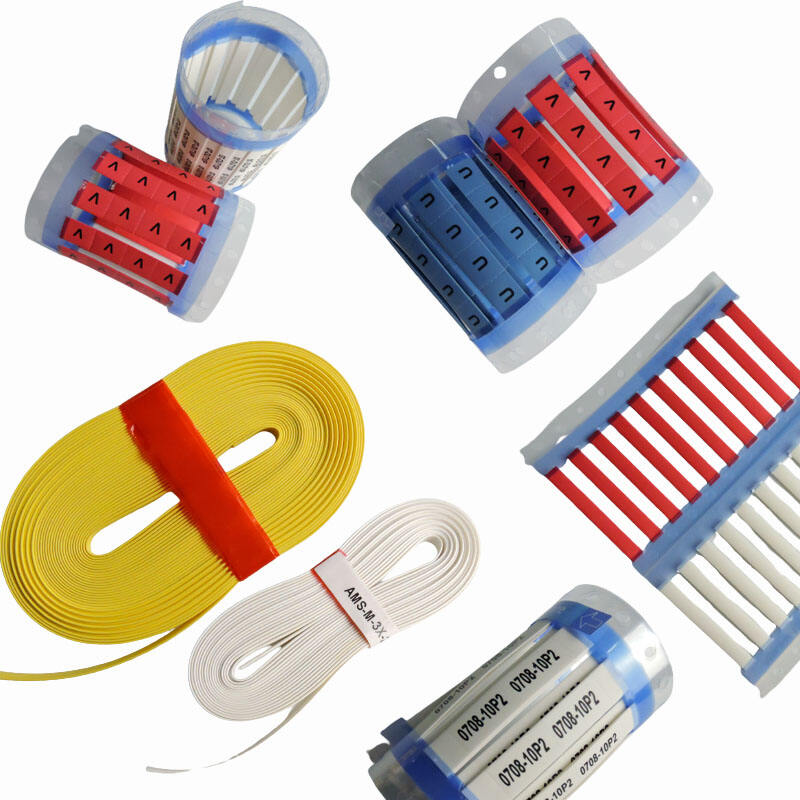

Presentatie van de Elektrische Kabelmarkeringslabel Huls Warmteshrinkbuis, de ultieme oplossing voor identificatie en organisatie van kabels. Dit innovatieve product vereenvoudigt al uw labelproblemen en garandeert efficiënte kabelbeheer in een snelle werkomgeving, waardoor het een onmisbaar accessoire wordt voor elk werkplek.

Dit warmteshrinkbuis is ontworpen met als doel om kabels eenvoudig te kunnen identificeren, vooral in geval van een storing of defect. Het vermindert de kans op aansluitsfouten en laat toe om cabling-systemen veel efficiënter bij te houden. De transparante labelmogelijkheid biedt een duidelijk zicht op de tekst, waardoor identificatie snel en gemakkelijk is.

Gemaakt van hoogwaardige, krimpende polyolefin, de Volsun Electric Cable Marker Label Mouw Warmteshrinkbuis waarborgt een hoge prestatie en duurzaamheid. Het houdt zijn vorm zelfs bij blootstelling aan ongunstige omstandigheden zoals chemicaliën, vloeistoffen en extreme temperaturen. Dit zorgt ervoor dat de tekst op de labels leesbaar blijft en dat de labels een eenvoudige manier bieden om de kabel te identificeren, zelfs na jarenlange gebruik.

Met een krimpverhouding van 3: 1 past dit krimpslang gemakkelijk om elke kabelgrootte. Nadat de huls is aangebracht, kan deze eenvoudig worden gekrompen met een gewone krachtschaar of aansteker, wat een geheugen-effect activeert om de oorspronkelijke grootte te behouden. Na het krimpen smelt de lijmachtige laag op de kabel, waardoor de huls stevig aan de draad vastzit. Het is eenvoudig toe te passen en vereist geen speciale gereedschap of expertise, wat het een handig product maakt voor iedereen.

De Volsun Electric Cable Marker Label Huls Krimpslang voldoet ook aan alle noodzakelijke veiligheidsvereisten, inclusief RoHS en UL 224 normen. Deze certificaten garanderen dat dit product vrij is van schadelijke stoffen en zorgen voor een hoge prestatie en langdurige duurzaamheid.

MSVLU MSVLU(C) Halogeen Vrij Milieu Vriendelijke Krimpbaar Draad Identificatie Hulzen Halogeen

Beschrijving

De reeks MSVLU is halogeen vrij, milieuvriendelijk, hitte-schrinkende identificatiesleeves. Het wordt gemaakt van gekruislinkt milieuvriendelijk polyolefin, behandeld met een krachtige elektronenstraal uit elektronenversnellers om de eisen van hoge markten te voldoen waarop betrouwbare, economische en milieuvriendelijke kabel- & draadidentificatie vereist is. Het voldoet aan de eisen van UL224, CAN/CSA C22.2. Shrinkverhoudingen van zowel 2:1 als 3:1 zijn beschikbaar. Raadpleeg de onderstaande tabellen.

Kenmerken

• Halogeen vrij, ideaal voor elektronische of elektrische schakelingen, communicatie, architectuurindustrieën

• Temperatuurresistentie: 125°C

• Hoog vuurbestendig, VW-1

• ROHS-compliant en voldoet aan SONY SS-00259

• Zeer betrouwbaar en permanent identificeren

• Gevoelig voor warmte, scheidt snel in

• Computergeletterde tekst of lettertypen ter uw beschikking.

• Standaardkleur: geel, wit

Gekwalificeerde temperatuur

• Continue werktemperatuur: -55°C~125°C/-67°F~257°F

• Min. samentrektemperatuur: 85°C/185°F

• Volledige hersteltemperatuur: 115°C~200°C/239°F~392°F, 8~3 minuten

• Max. opslag- en transporttemperatuur: ≤50°C/122°F

Normen

• Materiaalnorm: UL224, CAN/CSA C22.2

• Kleurcode integriteit: SAE-AS 81531 en MIL-STD-202F/215J

|

|

|

|

|

|

|

|

Eenheid |

|

|

|

|

|

|

Mpa |

|

|

ASTM G 154, MIL-DTL-23053E ISO 37, 500mm/min 175°C, 168h, ISO 188 |

|

|

|

|

|

|

Hitteoudering / Na vloeistoffen / UV-oudering |

|

|

|

|

% |

|

|

|

|

|

|

|

|

Hitteoudering / Na vloeistof |

|

|

|

|

Mpa |

|

|

ASTM D 882 |

|

|

|

|

|

V |

|

2500V, Geen doorbraak in 60 sec |

IEC 243, ASTM G 154 175°C, 168h, ISO 188 |

|

|

|

|

|

MV\/m |

|

|

|

|

|

|

|

|

Hitteoudering\/ Na vloeistof\/ UV-oudering |

|

|

|

|

ω. cm |

|

|

IEC 93 |

|

|

|

|

|

- |

|

|

ASTM 150 |

|

|

|

|

|

- |

|

|

ASTM 570, 23°C, 24h |

|

|

|

|

|

- |

|

|

23°C, Rh 95±5%, 24h 175°C, 16h |

|

|

|

|

|

- |

|

Geen barsten, vloeien, druppelen |

Winden op de gespecificeerde mander, 225°C, 4h |

|

|

|

|

|

- |

|

|

Winden op de gespecificeerde mander, -30°C, 1h |

|

|

|

|

|

- |

|

|

IEC 60332-1-3 Ed. 1.0 b: 2004 |

|

|

|

|

|

% |

|

|

200°C, Constant 3min |

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Uitgebreid zoals geleverd (mm) |

|

|

Hersteld na verhitting (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Uitgebreid zoals geleverd (mm) |

|

|

Hersteld na verhitting (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Opmerking: bijzondere maten en verpakkingen kunnen op aanvraag worden aangepast

Standaard verpakkinggegevens

Buitenlandse tentoonstelling

Handelstermen |

FOB, EXW, CIF, DDU, DDP, CFR |

Betalingsvoorwaarden |

T\/T, L\/C, Afneembaar |

MOQ |

1 |

Leveringscapaciteit |

1, 000, 000 stuks per maand |

Levertermijn |

gewoonlijk 5-7 werkdagen |

Zending |

Express, Lucht, Zee |

Haven |

Shanghai, Ningbo, Shenzhen |

monster beschikbaarheid |

Ja |

Monsters tijd |

meestal 1-2 dagen |

Verpakking |

Normaal: Plastic zak & Doos & Pallet

Speciaal: Gepersonaliseerd verpakken |