RoHS Reach UL High Voltage Karet Silicone Fiberglass Sleeve tabung kaca sleeve Lapisan Kaca Serat Silicone

Deskripsi

Volsun

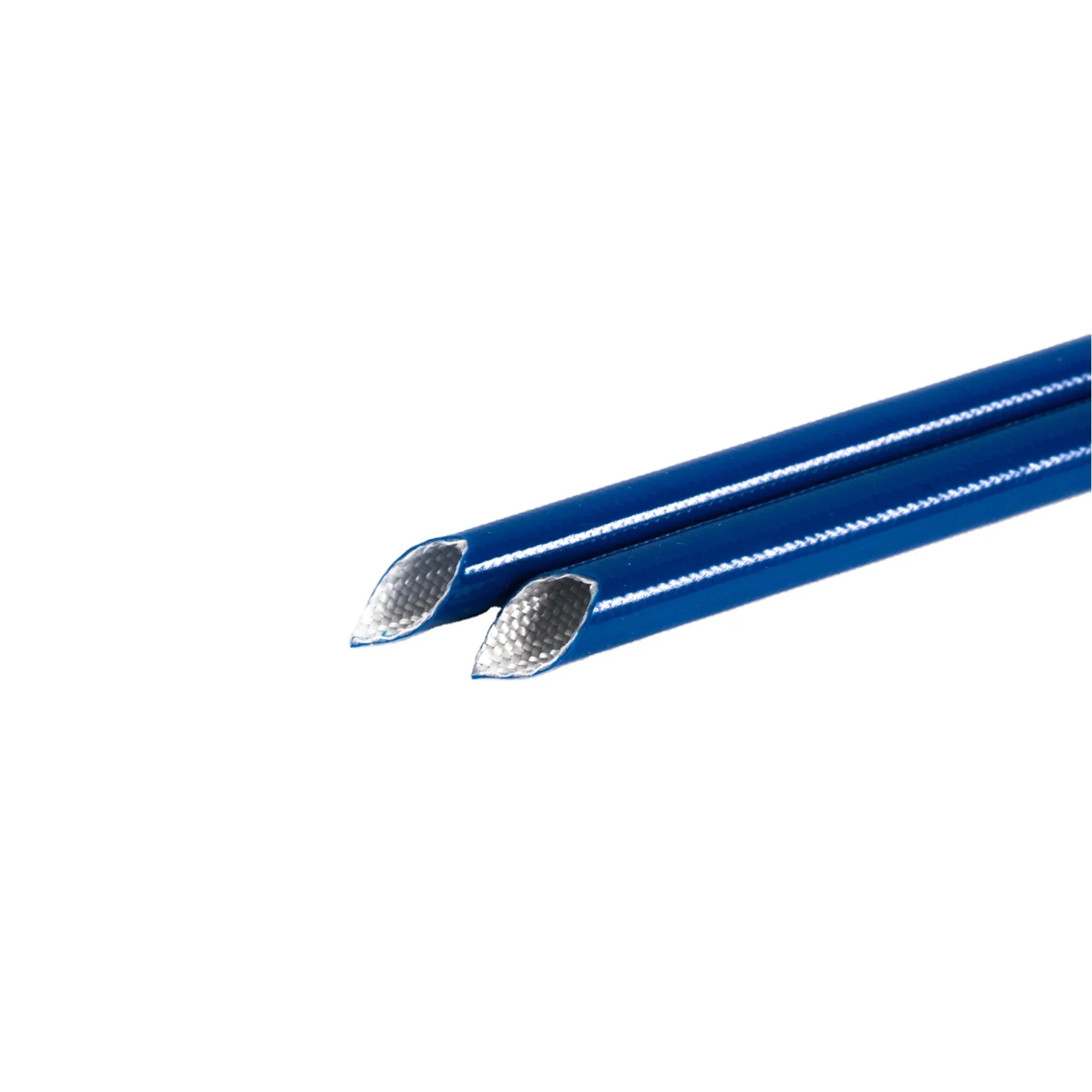

Selubung Karet Silicone Serat Kaca Tegangan Tinggi yang memenuhi RoHS Reach UL adalah tambahan yang sempurna untuk setiap proyek pemasangan kabel listrik. Selubung tabung serat kaca ini menawarkan perlindungan yang andal untuk kabel dan kawat, memastikan sistem listrik aman dan terjamin. Kapabilitas tegangan tingginya membuatnya cocok untuk berbagai aplikasi, termasuk industri otomotif, penerbangan, dan maritim.

Lapisan silicone pada tabung serat kaca membuatnya tahan terhadap air, minyak, dan bahan kimia, menjadikannya ideal untuk digunakan di lingkungan yang keras. The Volsun tabung juga tahan terhadap suhu tinggi, mampu menahan suhu hingga 200°C tanpa merusak performanya. Ini berarti bahwa Volsun RoHS Reach UL High Voltage Silicone Rubber Fiberglass Sleeve sangat cocok untuk digunakan dalam kondisi ekstrem di mana bahan lain mungkin gagal.

Selubung tabung mematuhi standar RoHS, Reach, dan UL, yang berarti dibuat dari bahan berkualitas tinggi yang aman untuk lingkungan. Kepatuhan RoHS dan Reach memastikan bahwa produk bebas dari zat berbahaya, dan sertifikasi UL menjamin bahwa ia dapat dengan aman menangani tegangan tinggi.

Selain kemampuan perlindungan luar biasanya, Volsun RoHS Reach UL High Voltage Silicone Rubber Fiberglass Sleeve mudah dipasang. Selubung tabung dapat dengan cepat dan mudah diluncurkan ke atas kabel dan kawat, serta mudah dipotong sesuai panjang yang diinginkan. Ini membuatnya menjadi solusi yang nyaman dan praktis untuk proyek-proyek listrik segala ukuran.

Lengan Karet Silicone Kaca Volsun RoHS Reach UL Tegangan Tinggi tersedia dalam berbagai ukuran untuk memenuhi kebutuhan Anda. Baik Anda mengerjakan proyek listrik kecil atau aplikasi industri besar, ada ukuran lengan tabung yang sesuai dengan kebutuhan Anda.

Lengan kaca fiberglass tegangan tinggi UL berbahan karet silikon untuk perlindungan harnes kabel

Barang |

Parameter Teknis |

Standar referensi |

Penampilan |

Tidak ada kebocoran lem, retak, dll |

GB/T 7113.1-2014 |

Hidrolisis lapisan |

Tidak ada pergeseran lapisan, perekatan, dll |

GB/T 7113.2 |

Uji pembengkokan dingin |

-40℃, 4h, Tidak ada retak, pengelupasan lapisan dan delaminasi |

IEC60684 |

Suhu |

-40℃~200℃ |

UL1441 |

Peringkat retardan api |

HB |

UL94 |

Tegangan Pecah |

Standar referensi |

GB/T 1408-2016 |

Ketahanan panas |

250℃±5, 24h, Tidak ada tetesan, tidak ada bekas aliran, tidak ada retakan |

JB\/T 7093 2015 |

Dimensi

D. Dalam (mm) |

Ketebalan Dinding (mm) |

Ketebalan Dinding (mm) |

Paket |

|||||||

Ukuran |

Toleransi |

1500V |

2500V |

4000v |

7000V |

M/ROLL |

||||

φ2.0 |

-0,10~0,25 |

0,35±0,1 |

0,40±0,1 |

0,45±0,1 |

0,5±0,1 |

100 |

||||

φ2.5 |

-0,10~0,25 |

0,35±0,1 |

0,40±0,1 |

0,45±0,1 |

0,5±0,1 |

100 |

||||

φ3.0 |

-0,10~0,25 |

0,35±0,1 |

0,40±0,1 |

0,45±0,1 |

0,5±0,1 |

100 |

||||

φ3.5 |

-0,10~0,35 |

0,4±0,1 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ4.0 |

-0,10~0,35 |

0,4±0,1 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ4.5 |

-0,10~0,35 |

0,4±0,1 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ5.0 |

-0,10~0,35 |

0,4±0,1 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ5.5 |

-0.10~0.40 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

0.60±0.1 |

100 |

||||

φ6.0 |

-0.10~0.40 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

0.60±0.1 |

100 |

||||

φ7.0 |

-0.10~0.50 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

0.60±0.1 |

100 |

||||

φ8.0 |

-0.10~0.50 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

0.65±0.1 |

50 |

||||

φ9.0 |

-0.10~0.50 |

0,45±0,1 |

0,50±0,1 |

0,55±0,1 |

0.65±0.1 |

50 |

||||

φ10.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

φ11.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

φ12.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

φ13.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

φ14.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

φ15.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Kami tidak mencantumkan semua ukuran di sini. Diameter 16mm-25mm juga dapat diproduksi

Pertunjukan perusahaan

Hingga saat ini, Volsun telah bekerja sama dengan pelanggan dari 88 negara, kami menawarkan solusi penyegelan dan ketahanan air yang sesuai untuk beberapa perusahaan terkenal di bidang komunikasi, otomotif, industri energi dll

Packing & Pengiriman

Syarat perdagangan |

FOB, EXW, CIF, DDU, DDP, CFR |

Ketentuan Pembayaran |

T/T, L/C, Negosiable |

MOQ |

1 |

Kemampuan pasokan |

1.000.000 mts per bulan |

Pimpin |

2-3 hari kerja |

Pengiriman |

Ekspres, Udara, Laut |

Pelabuhan |

Shanghai, Ningbo, Shenzhen |

Ketersediaan sampel |

Ya |

Contoh |

1-2 hari |

Kemasan |

Normal: Kantong plastik & Karton & Pallet Khusus: Kemasan kustom |

Sertifikat

Pameran Luar Negeri

J: Kami menerima T/T 50% uang muka dan 50% sisa pembayaran melawan B/L atau salinan L/C pada pandangan, juga menerima Western Union, VISA, dan Paypal.

P 2. Berapa waktu tunggu normal untuk pesanan produk?

J: Rata-rata waktu tunggu untuk prototipe/piece pertama adalah 7~10 hari, jika ada tooling, waktu tunggu untuk tooling produksi adalah

10 hari, dan rata-rata waktu produksi setelah persetujuan sampel adalah 2-3 minggu.

P 3. Apa kemasan standar Anda?

A: Semua barang akan dikemas dalam kardus dan dimuat di palet. Metode pengemasan khusus dapat diterima jika diperlukan.

P 4. Bisakah Anda memberi tahu kami kapasitas produksi bulanan produk Anda?

A: Ini tergantung pada modelnya, kami memproduksi lebih dari 1500 ton bahan karet per bulan.

P 5. Apa sertifikat apa saja yang Anda miliki?

A1: Kami memiliki sertifikasi ISO9001: 2015, IATF16949: 2016, ISO14001: 2015, ISO45001: 2018

A2: Kami memiliki berbagai kompon karet yang disetujui oleh UL, ROHS, dan REACH.

P6: Bagaimana cara memeriksa kualitas pesanan besar?

A1: Kami menyediakan sampel pra-produksi kepada semua pelanggan sebelum produksi massal jika diperlukan.

A3: Kami menerima inspeksi pihak ketiga, seperti SGS, TUV, INTERTEK, BV, dll

P 9: Apakah Anda bisa memberikan layanan kustom?

A: Ya, kami menerima kustomisasi dan dapat memproduksi produk dalam berbagai ukuran, kemasan, warna sesuai dengan permintaan.