Tub Ghearrthaisc Sílicéad do Mhiotar Gnó Nua Ard-Theoirnn 200 Céadshocair ROHS CN;JIA

Cur Síos

Volsun

Agus mar a théimid chun ár dtús ar fáil i gcás gutaí tréith, is éasca go mbeidh sé againn ag obair leis na componaintí ceart chun an-tréith a phógadh. Componán amháin mar sin é an Sílín Theirmiúil Sheilic. Brand líofa ar fheabhsú slnnte, tarraingimíd thú chuig sílín theirmiúil ardchaighdeán atá speisialta dírithe don nhódóg nua-éigeandála - an Sílín Theirmiúil Sheilic don Nhódóg Nua-Éigeandála Teochtard 200 Céad Insulation Sleeving ROHS CN; JIA.

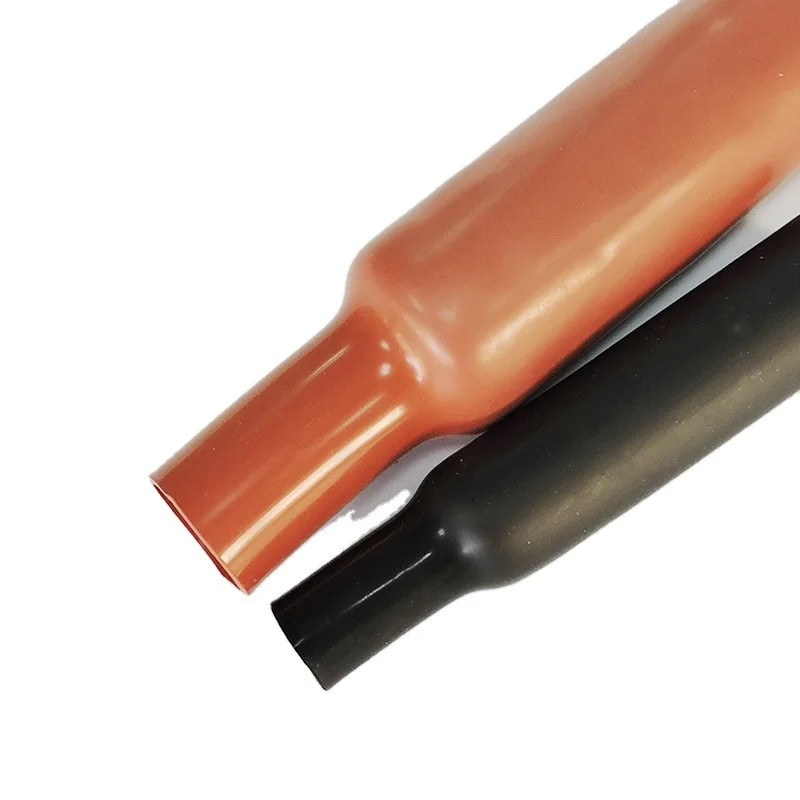

Is é seo túb leathnaithe sólásach uil-eolas ó Volsun atá déanta as mhaith sheilicíne a sholáthraíonn insuláidh agus cosaint earclú ar phéileanna tábhachtacha do mhótar gheimhridh eileactrais. Tá an túb láidir fliuch agus faightear a bheith ina chónaí i ngéarchéimí uasail, ag cinntiú go bhfuil sé an freagra ceart chun cosaint na mótaire ón gcineál téamh atá ag tarlú agus é ag oibrigh.

Úsáidtear an máterial seilicín sa Volsun Túb Leathnaithe Téamh seo agus tá tuiscint den chuma éagsúla de chuidanna timpeallachta mar shampla uisce, nádúrtha, agus briseadh, ag cinntiú go bhfuil sé rogha idéala don úsáid ina bhfuil neart cosaint ar chúram. Tá an túb comhlíonadh RoHS, a chiallaíonn nach bhfuil aon mhaiththeolaíochtaí ann, ag cinntiú go bhfuil sé slán chun úsáid i ngheimhridh eileactrais.

Tá Réit Sheirbhíse Téamh ag Volsun agus tá ráta thuiscintiúil 2: 1 aige, a chiallaíonn go gcuirfidh sé isteach go leith idirthe a chruaigh uirthi nuair a fheiceann téamh. Tabharfaidh an t-iarrthar seo réit shonrach do phléasanna éagsúla sa mhéid, cinntíonn sé cúram fite fuaite gan spás do chóiriú. Cúimsíonn an cúram seo cruthanna comhaid atá suimte faoi choinneál nó briseadh mar thoradh ar chruthaithe nó scuabadh, ag dul i ngleic le haicmí beatha na n-eangacha.

Is éasca an Réit Sheirbhíse Téamh Silicín ó Volsun a shuiteáil agus níor cheart aon chomhluacha speisialta nó tionscnaimh. Is féidir leat é a shuiteáil ag baint úsáide as phist téamh nó oiread eile de théamh mar thiocfada, cosúil le cúinne téamh. Tá na réití ar fáil in n-éagsúlacht maíreachtálacha chun díoltuithe ábharacha a dhéanamh, ag déanamh di réit fostaíochta iontach don ghnéithe éagsúla na neamhspleách.

Míreanna |

Luach tipiciúil |

Modh tástála |

Neart Tension |

6.5Mpa |

GB/T 528 |

Síneadh ag briseadh |

≥200% |

GB/T 528 |

Féirseacht Scailp |

14kN/m |

GB/T 529 |

An fhrithsheasmhacht tomhais |

≥2*10 14ω. cm |

ASTM D 876 |

Cumhacht dielectrach |

≥20kV/mm |

GB/T 1408 |

Méair atá ar fáil ó Φ0.8mm go Φ150mm |

||||||||

Méid(mm) |

I. D. Soláthartha (mm) |

Foghlach gairid roimh éirí (mm) |

Méid tar éis éirí (mm) |

|||||

Diaméadar inmheánach |

Tiús balla |

|||||||

φ 0.8 |

≥0.8 |

0.5±0.15 |

0.5±0.1 |

0.7±0.15 |

||||

φ 6.0 |

≥6.0 |

0.5±0.15 |

3.6±0.3 |

0.8±0.15 |

||||

φ 15 |

≥15.0 |

1.0±0.2 |

9.5±0.5 |

1.7±0.3 |

||||

φ40 |

≥40 |

1.1±0.3 |

29.5±3.0 |

2.0±0.3 |

||||

φ100 |

≥97 |

1.5±0.4 |

64.7±5.0 |

2.5±0.4 |

||||

φ150 |

≥147 |

1.5±0.4 |

88.20±5.0 |

2.5±0.4 |

||||

Is í an gceartas ár ngné. Tá córas bunaithe ag Volsun do bhainistiú ceartais, a chuí mar IATF16949, ISO9001 agus daoine eile. Agus tá titil láidre againn mar Chorpóras Gaeltachta na nEolaíochta i gCionnachta Súila, Eagraíocht Teicneolaíochta Ard-Nuálta na Sín agus daoine eile. Tá reachtaíocht intleacht idirnáisiúnta againn féin, 88 pataint agus 97 de chomhaid ceartaí

Go dtí anois, chomhraigh Volsun le custaiméirí as 88 náisiún, tugaimid freastalacha comhracacha agus fuaimeanna fuar oiriúnacha do chuid gairmiúil faoi deara i gcóras cumarsáide, Cárta, agus Gnó Phlé agus tuilleadh

Téarmaí trádála |

FOB, EXW, CIF, DDU, DDP, CFR |

Téarmaí Íocaíochta |

T/T, L/C, Comhracsa |

MOQ |

100pcs |

Néacsamhail um shroic |

1, 000, 000 mts gach seachtain |

Am Fhorais |

go háirithe 3-5 lá oibre |

Seachadadh |

Easpres, Spás, Mara |

Port |

Shanghai, Ningbo, Shenzhen |

Freedman samplacha |

Tá |

Am Samplú |

i gceist 1-3 lá |

Pacáiste |

Norma: Mála plásca & Cárta & Palad Speisialta: Pacáidí tuillte |