Volsun

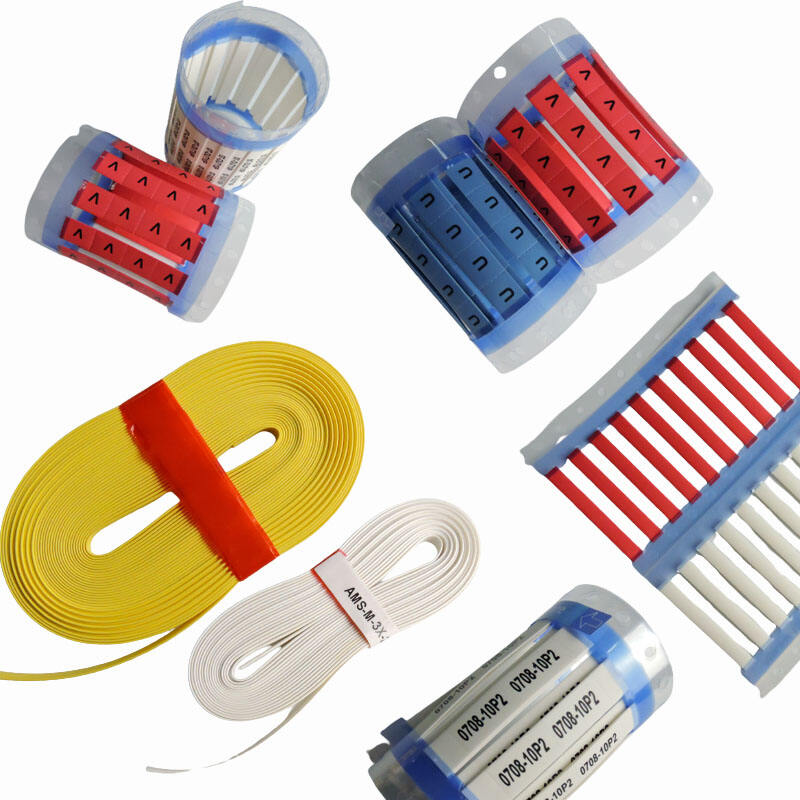

Tutustu Sähkökaapelimerkintä-merkki kouristin lämpötiivistyvä putki, äärimmäinen ratkaisu kaapleiden tunnistamiseen ja järjestelyyn. Tämä innovatiivinen tuote yksinkertaistaa kaikki merkitsemisongelmat ja varmistaa tehokkaan kaapelimenetelmän nopeassa ympäristössä, mikä tekee siitä välttämätön lisävaruste mille tahansa työpaikalle.

Tämä lämpökontraktio-putki on suunniteltu tarkoituksena helpottaa kaapeliennusteiden tunnistamista, erityisesti vikailmioiden tai häiriöiden tapauksessa. Se vähentää sähköjohtopien virheiden riskiä ja mahdollistaa järjestelmien seurannan tehokkaammin. Selkeä merkintökyky mahdollistaa tekstin helpon näkemisen, mikä nopeuttaa ja helpottaa tunnistamista.

Valmistettu korkealaatuisesta, kontraktiivisesta polyolefinitse, Volsun Sähkökaapelimerkintä-labeli Lämpökontraktio-putki takaa korkeanlaadun toiminnallisuuden ja kestävyyden. Se säilyttää muodonsa vaikka se altistuu epäsuotuisille olosuhteille, kuten kemikaaleille, vedelle ja äärimmäisille lämpötiloille. Tämä varmistaa, että merkinnät pysyvät luettomina, ja että ne tarjoavat helpon tapan tunnistaa kaapeli vuosien kuluttua käytöstä.

Pienennyskerroksella 3:1 tämä lämpöpienenevä putki soveltuu helposti minkään kokoisen kaapin ympärille. Kun huppa on asetettu paikoilleen, sen voi helposti pienentää tavallisen lämpöpistolan tai liekin avulla, mikä aktivoi muistieffektin palauttaakseen alkuperäisen koon. Pienennettyjen jälkeen liimaisuus sisustuu kaapeen päälle, kiinnittämällä hupan vahvasti johdolle. Se on helppo käyttää eikä vaadi erityisiä työkaluja tai taitoja, mikä tekee siitä hyödyllisen tuotteen kaikille.

Volsun Electric Cable Marker-merkintähuppa lämpöpienenevä putki täyttää myös kaikki tarvittavat turvallisuusvaatimukset, mukaan lukien RoHS- ja UL 224 -normit. Nämä todistukset varmistavat, että tämä tuote on vapaana kaikista vaarallisista aineista ja takaa korkean suorituskyvyn sekä pitkäkestoisuuden.

MSVLU MSVLU(C) Halkijoiden Vapaa Ympäristöystävällinen Lämpöpienenevä Kaapimerkintähuppa Halkijoiden

Kuvaus

MSVLU-sarja on hapolittomia, ympäristöystävällisiä ja lämpöpienteneviä tunnistussleeveejä. Se valmistetaan risteämisteknologiassa käyttämällä ympäristöystävällistä polyolefina, jota bombardoidaan korkean voiman elektronisäteillä sähkökiihdyttimillä, jotta se vastaa korkean tason markkinoiden vaatimuksia, joilla tarvitaan luotettavaa, taloudellista ja ympäristöystävällistä kaapeli- ja johtotunnistusta. Se täyttää UL224:n ja CAN/CSA C22.2:n vaatimukset. Pientumissuhde 2:1 ja 3:1 on saatavilla. Katso alla olevat taulukot.

PIIRTEITÄ

• Hapolittomat, ideaalisesti käytettävissä elektronisen tai sähköisen piirien, viestinnän ja rakennusalan teollisuudessa

• Lämpökestävyys: 125°C

• Korkeasti liekitukevia, VW-1

• ROHS-yhteensopiva ja täyttää SONY:n SS-00259:n

• Korkealaatuinen ja pysyvä tunnistaminen

• Lämpöherkkä, pienenee nopeasti

• Tietokoneelliset kirjaimet tai fontit käytettävissäsi.

• Perusväri: keltainen, valkoinen

Luokitettu lämpötila

• Jatkuva käyttölämpötila: -55°C~125°C/-67°F~257°F

• Min. suppenemislämpötila: 85°C/185°F

• Täysi palautumislämpötila: 115°C~200°C/239°F~392°F, 8~3 minuuttia

• Maksimi varastointi- ja kuljetuslämpötila: ≤50°C/122°F

Standardit

• Materiaalietujuus: UL224, CAN/CSA C22.2

• Värikoodin lujuus: SAE-AS 81531 ja MIL-STD-202F/215J

|

|

|

|

|

|

|

|

Yksikkö |

|

|

|

|

|

|

MPa |

|

|

ASTM G 154, MIL-DTL-23053E ISO 37, 500mm/min 175°C, 168h, ISO 188 |

|

|

|

|

|

|

Lämpöikävyttynyt / Jälkeen virtausaineet / UV-ikävyttynyt |

|

|

|

Pituuden kasvu murtumispisteessä |

% |

|

|

|

|

|

|

|

|

Lämpöikävyttynyt / Jälkeen virtausaine |

|

|

|

|

MPa |

|

|

ASTM D 882 |

|

|

|

|

|

V |

Ei ikävyyttä / Jälkeen ikävytystestin |

2500V, Ei läpimurtoa 60 sekunnissa |

IEC 243, ASTM G 154 175°C, 168h, ISO 188 |

|

|

|

|

|

MV/m |

|

|

|

|

|

|

|

|

Lämpöikäytetty / Jälkeen vedestä / UV-ikäytetty |

|

|

|

|

ω. cm |

|

|

IEC 93 |

|

|

|

|

|

- |

|

|

ASTM 150 |

|

|

|

|

|

- |

|

|

ASTM 570, 23°C, 24h |

|

|

|

|

|

- |

|

|

23°C, Rh 95±5%, 24h 175°C, 16h |

|

|

|

|

|

- |

|

Ei hajoamista, virtaamista tai putoamista |

Käännös määrättyyn mandreliin, 225°C, 4h |

|

|

|

|

|

- |

|

|

Käännös määrättyyn mandreliin, -30°C, 1h |

|

|

|

|

|

- |

|

|

IEC 60332-1-3 Ed. 1.0 b: 2004 |

|

|

|

|

|

% |

|

|

200°C, Jatkuva 3min |

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Laajennettu toimituksessa (mm) |

|

|

Palautunut lämpötilan jälkeen (mm) |

|

|

|

|

|

|

Yksitoista seinän paksuus h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Laajennettu toimituksessa (mm) |

|

|

Palautunut lämpötilan jälkeen (mm) |

|

|

|

|

|

|

Yksitoista seinän paksuus h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Huomautus: Erityiskokojen ja pakkausten mukauttaminen on mahdollista pyyntöjen mukaan

Kauppakelpoisuus |

FOB, EXW, CIF, DDU, DDP, CFR |

Maksuehdot |

T/T, L/C, Neuvottelukelpoinen |

MOQ |

1 |

Toimituskyky |

1 000 000 kappaletta kuukaudessa |

Toimitusaika |

yleensä 5-7 arkipäivää |

Toimitus |

Express, Ilma, Meri |

Satama |

Shanghai, Ningbo, Shenzhen |

Näyte saatavilla |

Kyllä |

Näyteaika |

yleensä 1-2 päivää |

Pakkaus |

Normaali: Muovikysi ja Kartonki ja Paletti

Erikoispyyntö: Muita pakkausmuotoja |