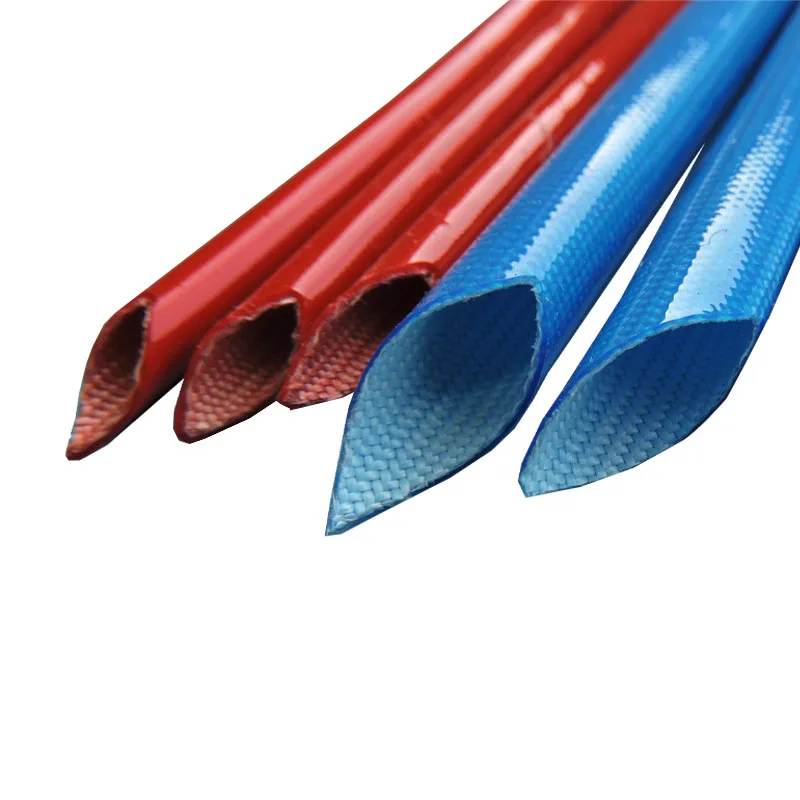

6mm Hochspannung Glasfaserschlauch mit Silikonbeschichtung Silikonbeschichteter Glasfaserschlauch

Beschreibung

Volsun

Suchen Sie eine zuverlässige und haltbare Isolierlösung für Ihre Hochspannungsanwendungen? Suchen Sie nicht weiter als den 6mm Hochspannungssilikonglasfaserärmel mit silikonbeschichteter Glasfaserverkleidung.

Dieses hochwertige Produkt wird aus Premium-Silikon- und Glasfasermaterialien hergestellt, was eine maximale Schutz- und Isolierungsfunktion für Ihre wertvollen Geräte und Systeme gewährleistet. Es Volsun hat einen Durchmesser von 6mm, was es die perfekte Größe für eine Vielzahl von Anwendungen in nahezu jeder Branche macht.

Was unterscheidet Volsuns Hochspannungssilikon-Glasfaserärmel mit silikonschwarzem Glasfaserrohr von anderen Isolierprodukten auf dem heutigen Markt? Zunächst bietet es eine überlegene Widerstandsfähigkeit gegen Hitze, Flammen, Chemikalien und andere Umwelteinflüsse, die die Integrität Ihrer Systeme gefährden könnten.

Darüber hinaus ist dieser robuste Isolierärmel so konzipiert, dass er hohe Spannungen und elektrische Ströme aushält, ohne sich zu verflüssigen oder seine Isoliereigenschaften zu verlieren. Er ist außerdem sehr flexibel und einfach zu installieren, was bedeutet, dass Sie Ihre Anlagen schnell wieder in Betrieb nehmen können und minimale Störungen Ihrer Produktionsprozesse haben.

Ob Sie also im Luft- und Raumfahrtbereich, in der Automobilindustrie, im Elektrobranchen oder in einer anderen Branche tätig sind, die zuverlässige Isolierlösungen benötigt, ist Volsuns 6mm Hochspannungssilikon-Glasfasermanschette mit silikongebauter Glasfaserröhre die ideale Wahl. Mit ihrer außergewöhnlichen Qualität, Haltbarkeit und Leistung können Sie sicher sein, dass Ihre Systeme noch viele Jahre lang geschützt sind.

UL Hochspannungssilikonkautschuk-Glasfasermanschette, gewebte Glasfasermanschette zum Schutz von Kabelbündeln

Artikel |

Technische Parameter |

Referenznorm |

Erscheinung |

Kein Klebstoffaustritt, Risse usw. |

GB/T 7113.1-2014 |

Kohlenstoffhydratlyse |

Keine Beschichtungsverschiebung, Haftung usw. |

GB/T 7113.2 |

Kaltbiegetest |

-40℃, 4h, Keine Risse, Beschichtungsablösung und Schichtenlösigkeit |

IEC60684 |

Temperatur |

-40℃~200℃ |

UL1441 |

Flammschutzklasse |

HB |

UL94 |

Durchschlagsspannung |

Referenznorm |

GB/T 1408-2016 |

Wärmebeständigkeit |

250℃±5, 24h, Keine Tropfen, keine Fließspuren, kein Riss |

JB/T 7093 2015 |

Abmessungen

I. D. (mm) |

Wandstärke (mm) |

Wandstärke (mm) |

Verpackung |

|||||||

Größe |

Toleranz |

1500V |

mit einer Leistung von |

4 000 V |

7000V |

M/ROLL |

||||

φ2.0 |

-0.10 bis 0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

φ2.5 |

-0.10 bis 0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

φ3,0 |

-0.10 bis 0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

φ3,5 |

-0.10 bis 0.35 |

0,4±0,1 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ4,0 |

-0.10 bis 0.35 |

0,4±0,1 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ4,5 |

-0.10 bis 0.35 |

0,4±0,1 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ5,0 |

-0.10 bis 0.35 |

0,4±0,1 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

100 |

||||

φ5,5 |

-0,10~0,40 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

0,60±0,1 |

100 |

||||

φ6,0 |

-0,10~0,40 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

0,60±0,1 |

100 |

||||

φ7.0 |

-0,10~0,50 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

0,60±0,1 |

100 |

||||

φ8,0 |

-0,10~0,50 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

0,65±0,1 |

50 |

||||

φ9,0 |

-0,10~0,50 |

0.45±0.1 |

0,50±0,1 |

0,55±0,1 |

0,65±0,1 |

50 |

||||

φ10,0 |

-0,20~0,70 |

0,50±0,15 |

0,55±0,15 |

0,65±0,15 |

0.7±0.15 |

50 |

||||

φ11,0 |

-0,20~0,70 |

0,50±0,15 |

0,55±0,15 |

0,65±0,15 |

0.7±0.15 |

50 |

||||

φ12,0 |

-0,20~0,70 |

0,50±0,15 |

0,55±0,15 |

0,65±0,15 |

0.7±0.15 |

50 |

||||

φ13,0 |

-0,30~0,80 |

0,55±0,15 |

0,60±0,15 |

0,70±0,15 |

0,75±0,15 |

50 |

||||

φ14,0 |

-0,30~0,80 |

0,55±0,15 |

0,60±0,15 |

0,70±0,15 |

0,75±0,15 |

50 |

||||

φ15,0 |

-0,30~0,80 |

0,55±0,15 |

0,60±0,15 |

0,70±0,15 |

0,75±0,15 |

50 |

||||

Wir führen nicht alle Größen hier auf. Durchmesser 16mm-25mm kann ebenfalls hergestellt werden.

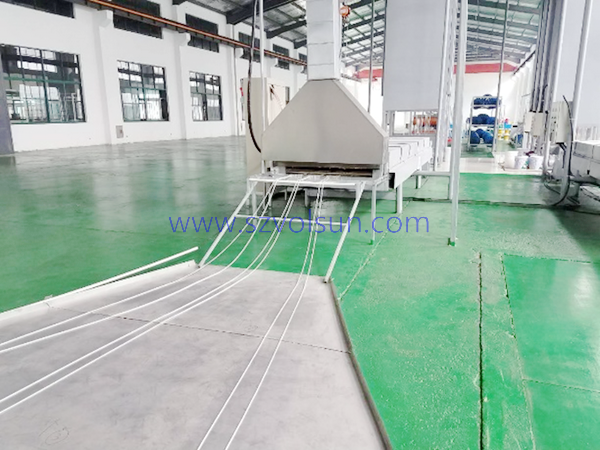

Firmen-Show

Bis heute hat Volsun mit Kunden aus 88 Ländern zusammengearbeitet und bietet passende Dichtungs- und wasserdichte Lösungen für einige bekannte Unternehmen in den Bereichen Telekommunikation, Automobilindustrie und Energieerzeugung an.

Verpackung & Lieferung

Handelsbedingungen |

FOB, EXW, CIF, DDU, DDP, CFR |

Zahlungsbedingungen |

T/T, L/C, Verhandelbar |

MOQ |

1 |

Lieferfähigkeit |

1.000.000 m pro Monat |

Führen |

2-3 Werkstage |

Versand |

Express, Luft, See |

Hafen |

Shanghai, Ningbo, Shenzhen |

Probe Verfügbarkeit |

Ja |

Muster |

1-2 Tage |

Verpackung |

Normal: Kunststoffbeutel & Karton & Palett Spezial: Individuelle Verpackung |

Zertifikat

Auslandsmesse

A: Wir akzeptieren T/T 50% Anzahlung und 50% Restbetrag gegen B/L oder L/C Kopie auf Ersten Blick, wir akzeptieren auch Western Union, VISA und Paypal.

F 2. Was ist die normale Lieferzeit für Produktbestellungen?

A: Die durchschnittliche Lieferzeit für Prototyp/Erststück beträgt 7~10 Tage, falls Werkzeugen involviert sind, beträgt die Lieferzeit für Produktionswerkzeuge 10 Tage, und die durchschnittliche Produktionszeit nach Stichprobengenehmigung beträgt 2-3 Wochen.

F 3. Was ist Ihre Standardverpackung?

A: Alle Waren werden in Kartons verpackt und auf Paletten geladen. Spezielle Verpackungsmethoden sind bei Bedarf möglich.

F 4. Können Sie uns die monatliche Produktionskapazität Ihrer Produkte nennen?

A: Das hängt vom Modell ab, wir produzieren mehr als 1500 Tonnen Kautschukmaterialien pro Monat.

F 5. Welche Zertifikate haben Sie?

A1: Wir sind nach ISO9001: 2015, IATF16949: 2016, ISO14001: 2015 und ISO45001: 2018 zertifiziert.

A2: Wir haben verschiedene Kautschukmischungen, die von UL, ROHS und REACH genehmigt wurden.

Q6: Wie kann die Qualität der Massenbestellung überprüft werden?

A1: Wir bieten allen Kunden, wenn nötig, Vorproduktionsproben an, bevor die Massenproduktion beginnt.

A3: Wir akzeptieren Drittanbieter-Inspektionen, wie SGS, TUV, INTERTEK, BV usw.

Q 9: Können Sie individuelle Dienstleistungen anbieten?

A: Ja, wir akzeptieren Anpassungen und können Produkte in verschiedenen Größen, Verpackungen und Farben entsprechend den Anforderungen herstellen.