Volsun

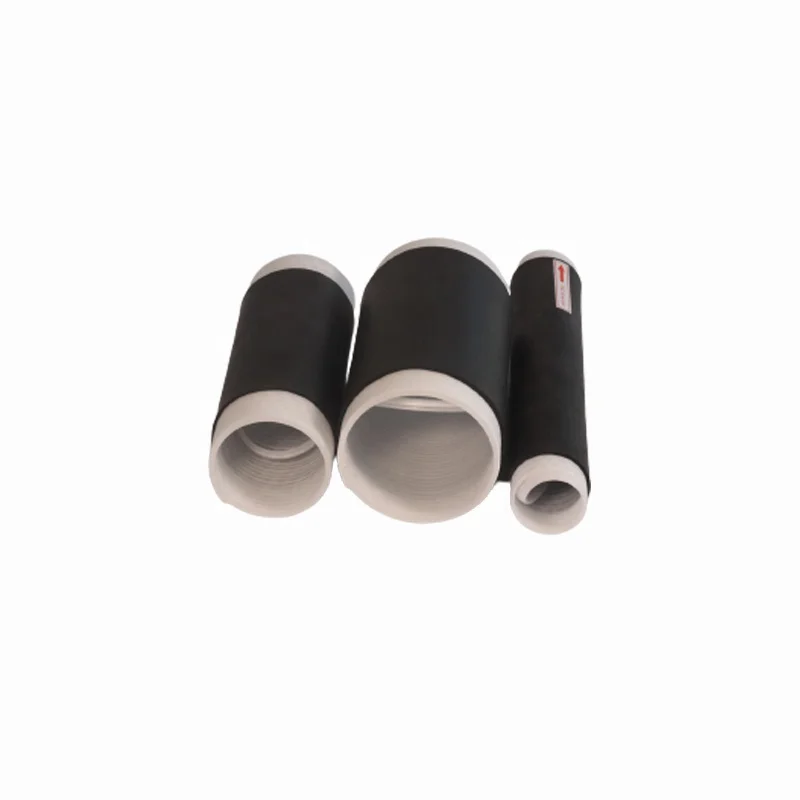

EPDM Koldtrækkingsrør er en høj kvalitet kabelforlystning, der giver ubetinget beskyttelse og isolation af dine kabler. Dette produkt er designet specifikt til at holde dine kabler sikre mod strenge vejrforhold, fugt, støv og andre ydre elementer, der kan forårsage skade.

En af de mest bemærkelsesværdige funktioner ved Volsun EPDM Cold Shrink Tubes er, at de er meget nemme at installere og kræver ingen yderligere værktøjer eller udstyr. Den kolde shrink-teknologi, der bruges i dette produkt, gør det muligt at installere hurtigt og uden anstrengelse, hvilket gør det til en fremragende valgmulighed for alle, der søger et pålideligt og problemfrit kabelfodering.

Denne rørings er tilgængelig i sort farve, hvilket gør den til en perfekt løsning for alle typer af ledninger, herunder dem, der kræver forbedret UV-skyldning. Den Volsun sorte farve giver også produkterne et elegant og professionelt udseende, hvilket gør dem ideelle til handels- og industrielle anvendelser.

Volsun EPDM Cold Shrink Tubes kommer i en række størrelser, så du altid kan finde den perfekte pasform til dine ledninger, uanset deres diameter. Det gratis prøveeksemplar, der er tilgængeligt for dette produkt, gør det nemt for dig at teste røringerne og sikre, at de passer til dine ledninger, før du køber.

Laves af højkvalitets EPDM-materiale, er disse cold shrink ærmer udformet til at klare ekstreme temperaturer og strenge forhold, hvilket sikrer, at dine kabler altid er godt beskyttet. EPDM-materialet giver også fremragende vandtæthed, hvilket er afgørende for at forhindre vandindtrængen og reducere risikoen for kabelskade.

RUBLS-EPDM er en serie af åbne ender, tubulære gummiærmer, der er udvidet i fabrikken og monteret på en fjernebar kerne. De leveres i denne forud strakte tilstand til feltinstallation. Kernen fjernes, når røret er blevet positioneret til installation over en inline-forbindelse, terminal-låg osv., hvilket tillader, at røret skrumper sammen og danner en vandtæt forsegling. Isoleringsslangerne er lavet af EPDM-gummi, der ikke indeholder chlorider eller sulfure. Forskellige diameterstørrelser vil dække en række 1000 volt-kabler, herunder kobber- og aluminiumledninger.

Egenskaber:

• Udmærket vejrbestandighed, ultraviolette ældningsmodstand og højere embrittlement modstand end varmeindtrækkende rør

• Modstandsdygtigere over for plade- og prikning, skurvning, syre og base end silicon koldeindtrækkende rør

• Udvider og indtrækker samtidig med arbejdsstykkerne uden mellemrum, lutter godt i hård miljø

• Stabil tætning af arbejdsstykker i blæsende miljø

• Velegnet til kabler under 1KV

• Lutter godt, beholder sin elasticitet og tryk selv efter mange år med ældreprocesser og eksponering

• Enkel og sikker installation, kræver ingen værktøjer eller særlig uddannelse. Ingen brændere eller varme arbejde nødvendigt

• Diameter indtrækning: ±50%

• Tætningsklasse IP68

|

|

Min. kabelyderdiameter (mm) |

Max. kabelyderdiameter (mm) |

Fuld gendannede længde (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Handelsbetingelser |

FOB, EXW, CIF, DDU, DDP, CFR |

Betalingsbetingelser |

T\/T, L\/C, Forhandlbar |

Leveringskapacitet |

1.000.000 stk pr. måned |

Leveringstid |

normalt 2-3 hverdage |

Forsendelse |

Ekspres, Luft, Hav |

Havne |

Shanghai, Ningbo, Shenzhen |

Prøve tilgængelighed |

Ja |

Prøvetid |

vanligvis 1-2 dage |

Indpakning |

Normalt: Plastikpose & Kasse & Palle

Særligt: Tilpasset pakning

|

Spørgsmål 1. Hvor længe er betalingsbetingelserne?

Svar: Vi accepterer T/T 50% indbetaling og 50% restbeløb mod B/L eller L/C kopier ved førstevisning, vi accepterer også Western Union, VISA og Paypal.

Spørgsmål 2. Hvad er den normale leveringstid for produktafleveringer?

Svar: Gennemsnitlig leveringstid for prototype/første stykke er 7~10 dage, hvis der er redskaber involveret, er produktionstiden for redskaber

10 dage, og gennemsnitlig produktionstid efter godkendelse af prøve er 2-3 uger.

Spørgsmål 3. Hvad er jeres standardpakning?

A: Alle varer vil blive pakket i kartoner og indlæst på paletter. Specielle pakningsmetoder er acceptabelt, når det er nødvendigt.

Spørgsmål 4. Kan du fortælle os den månedlige produceringskapacitet for jeres produkter?

A: Det afhænger af modellen, vi producerer mere end 1500 tons gummi-materialer hver måned.

Spørgsmål 5. Hvad for slags certifikater har I?

A1: Vi er certificeret til ISO9001: 2015, IATF16949: 2016, ISO14001: 2015, ISO45001: 2018

A2: Vi har forskellige gummi blandinger godkendt af UL, ROHS og REACH.

Q6: Hvordan kontrollerer man kvaliteten på en større bestilling?

A1: Vi tilbyder prøvefremstillinger til alle kunder før masseproduktion, hvis det ønskes.

A3: Vi accepterer tredjepartsinspektion, såsom SGS, TUV, INTERTEK, BV, osv.

Q 9: Kan I levere tilpasset service?

A: Ja, vi accepterer tilpasning og kan producere produkter i forskellige størrelser, emballage og farver efter krav.